Our Location

Brazing made by miller welders is widely used in different types of material, such as steel, aluminum, titanium, alloy, tungsten, plastic, and copper.

1) Welder brand:miller welders

2) Weldings: brazing

3) Tools: brazing welder

Brazing is a process that involves joining metal surfaces using a filler metal with a low melting point. The process relies on capillary action, where the homogeneous liquid flow of the filler material bonds with the base metals while maintaining their mechanical properties. This is particularly useful in applications such as silver brazing or other similar metals.

Brazing can be performed in different ways: localized heating, where only the joint area is heated, and diffuse heating, where the entire object is heated. During the brazing process, the joining metal is melted and filled into the joint of the two parent metals using capillary action. A flux protects the liquid metal from oxidation during its liquid stage. When liquid metal solidifies, it forms a strong bond between the two pieces.

Brazing is typically used to join metals like aluminum, cast iron, magnesium, copper, and silver. To ensure that the brazed joint possesses the expected mechanical properties, the brazing temperatures must efficiently conduct a suitable liquid flow from the molten braze alloy into the joints. Filler metals must also achieve proper wetting conditions to create strong bonds.

If you are looking for an instant manufacturing quote online, use your.STP files to get a quote in seconds. Enze provides short lead times and delivery options.

Brazing is often compared with soldering. While brazing uses capillary action to join different metal surfaces, soldering uses filler metals with a lower melting point than brazing. Braze welding is a MIG/MAG welding type, where the filler wires have a significantly lower melting point than the parent metal. The filler metal is deposited to fill in the gaps via capillary action, and while there may be some fusion of the parent metals, it is limited.

Brazing employs various heating methods to meet diverse purposes and applications. Heat can be applied directly to a joint (localized) or the whole workpiece (diffuse heating).

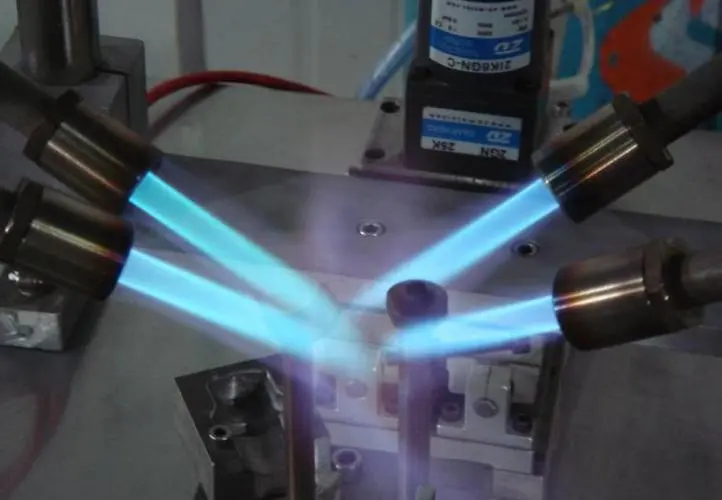

Torch brazing is a technique that uses a combination of acetylene, propane, hydrogen, and oxygen to create combusted fuel gas, which heats and melts the filler metal. Flux is used while employing this technique to protect the joint, which later requires post-cleanup. This method is mainly used for small assemblies with unequal metal weight. The process is often performed using gas welding equipment.

Furnace brazing and dip brazing are used in metallurgy to heat metals to the desired temperature. Furnace brazing uses gas firing or heating elements to heat the furnace while dip brazing involves immersing the workpiece or assembly in a bath of molten filler metal or molten salt.

Brazing offers several advantages over welding. It can join dissimilar metals, has high production rates, consumes less power, and produces cleaner joints without melting the base metals. However, brazed joints are weaker than welded joints and require tight, uniform joint gaps to achieve capillary action.

Enze’s manufacturing partners have experience and expertise in brazing, making it a flexible technique used in various industries to join dissimilar metals.