Our Location

Enze Mfg Co.Ltd. offers innovative, reliable, long-lifecycle CNC machining, sheet metal fabrication, rapid prototyping, forging, mold making, and surface finishing services. Our team, plant, and lab give us the skills to innovate and serve our clients on a higher level. For 10 years, we have focused on our services with a long-term and human-centric approach. We aim to be one of China’s best CNC machining and metal stamping suppliers to become a leading expert and help customers succeed and create a more sustainable tomorrow.

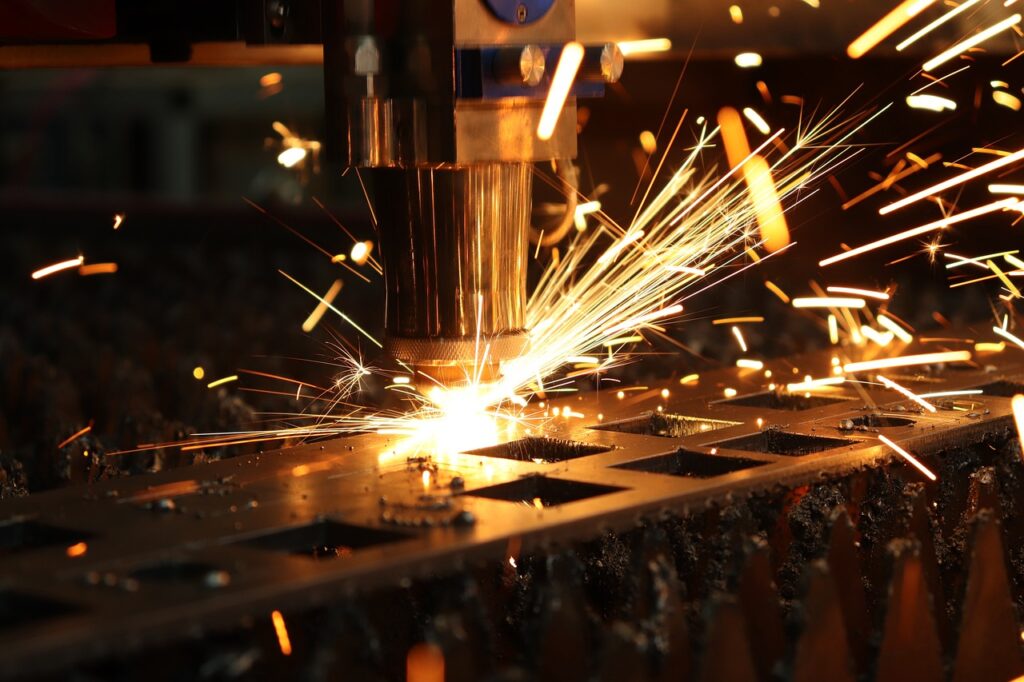

CNC machining is a subtractive manufacturing process using computerized instructions to perform various manufacturing tasks accurately. Enze provides clients with a reliable CNC machining service. We use 3-axis, 4-axis, and 5-axis indexed milling processes to manufacture parts from more than 35 engineering-grade plastics and metals.

Sheet metal fabrication forms flat sheets of steel or aluminum to the desired shape using different techniques, such as cutting, stamping, bending, and assembling. Enze’s custom sheet metal fabrication offers a fast and cost-effective solution for your projects.

Metal forging is a forming process that presses the material into a custom shape under the pressure of forging dies. As one of China’s leading metal forging manufacturers, Enze provides the reliability and quality of high-performance forged steel parts to meet your specifications in various metal materials.

Rapid prototyping is a manufacturing technique for creating high-quality physical models with 3D design concepts. Prototypes are useful in design development and improvement as they are a significant basis for production or engineering testing.

Mold-making is a manufacturing process to duplicate three-dimensional models or objects. Enze applies strict quality standards to every mold to ensure the consistency and excellent quality of the molded parts. Our team works with customers from prototyping through production to optimize rapid tooling for prototypes and components.

Surface finishing is a process used to modify the part’s surface to give it a desired individual appearance. Enze Manufacturing’s dedicated in-house powder coating plant ensures tight control of efficiency and delivery and guarantees that quality remains our highest priority.

Curated Products

Customers

Exporting Countries

Lightweight metals play a crucial role in the manufacturing of parts, particularly in the automotive,…

A splined shaft has a series of ridges or grooves (called splines) along its length.…

Aluminum is a versatile material that plays an important role across industries such as automotive,…

Our team and factory give us the skills to innovate and serve our customers with a high reputation. We offer our clients multiple materials and surface finishing options for a one-stop manufacturing experience.

We have over 500 workers, including 100 engineers, technicians and inspectors. Our team and equipment assure to accelerate the production of your prototypes or parts.

Our market is 50% in China and 50% overseas. We export our parts to East Asia, West Europe, the USA, and the Middle East.

We have over 800 CNC machines, presses, laser cutting machines, bending machines, and welding robots. This number is constantly changing. More types of devices are available if customers need them.

We have two major manufacturing facilities; all the custom parts are designed and manufactured in China.

We are pleased to establish a business relationship with our customer—advanced payment for initial cooperation. We can negotiate further payment terms in the future.

The PDF file is the most common file we use in producing. 3D files from CAD systems also can be accepted. Samples could be copied as an example in mass production if without any file.

Our services cover various industries, from automotive to semiconductor and agriculture to elevator.

See Industry of CNC Machining for details.

Contact us, you’ll get a constant quote within hours with free design feedback.