Our Location

Rapid Prototyping is critical to product development, enabling design teams to experiment and create functional prototypes. However, creating prototypes can be expensive and time-consuming. Traditional production processes, like CNC machining, require tool acquisition and setup, making custom prototyping costly and slow. Rapid Prototyping solves this problem by transforming ideas into real products faster. Engineers and product designers can develop prototypes quickly from CAD data and make changes based on feedback.

Rapid prototyping is a manufacturing technique for creating high-quality physical models with 3D design concepts. Prototypes are useful in design development and improvement as they are a significant basis for production or engineering testing. Prototyping is quick and economical for both personal companies and research institutions since they do not need to invest in mold equipment. Speed and affordability are the key features of rapid prototyping. As the name suggests, it emphasizes a fast turnaround time. Therefore, it is expected to produce a physical part quickly to validate the design and capture business opportunities.

Rapid CNC machining is a conventional prototyping method and a widespread way for metal prototyping. Enze has rich experience in various CNC prototype manufacturing for ten years. We cater to various industries, such as automotive, electronics, energy, medical, etc. CNC machining prototyping provides the best precision and surface finishes. Additionally, there is no limit to the selection of materials. However, CNC machining takes a long time to prepare and set up, so we always use this technology for high-precision and metal-material prototypes.

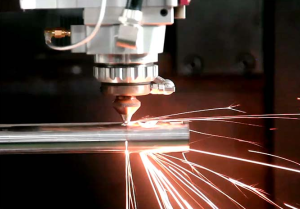

Enze’s rapid sheet metal fabrication services offer a fast and cost-effective solution for your projects—services including bending, spinning, drawing, and stretching. Sheet metal fabrication produces durable parts with various materials and finishes that meet your requirements.

Different prototyping processes have their unique advantages and limitations. The most commonly used techniques are CNC machining, 3D printing, injection molding, die casting, and sheet metal fabrication.

CNC machining offers tight tolerance and high-quality output, but it tends to generate raw materials waste and can be slow for large-volume production.

3D printing, on the other hand, excels in producing complex geometries, high-resistance parts, and scalable prototypes in various materials such as plastics, metals, and elastomers. However, surface quality can be limited.

Injection molding is known for its high repeatability and ability to create near-net final shapes. It is best suited for mass production of thin, complexly shaped products. However, some tooling is expensive and not suitable for small volume production.

Die casting is ideal for mass production of thin-walled metal prototypes made from aluminum and zinc alloys. However, it only supports non-ferrous metals and is unsuitable for small-volume production.

Sheet metal fabrication offers many forming processes and can easily make XL parts. It is appropriate for thin-walled metal prototypes, but only a limited metal can be used.

Every process has advantages and limitations. CNC machining is best suited for full-functional automotive prototypes and prototype molds. 3D printing is ideal for creating prototypes of small consumer goods and silicone prototypes. Injection molding is best for creating sink faucet parts, connector housing, enclosures, and panels. Die casting is suitable for producing prototype brackets and chassis, while sheet metal is ideal for making enclosures and panels.

Rapid prototyping services offer numerous benefits for your business. The outstanding advantages of this method are as follows:

1. Easy to transform designs into a physical sample: Rapid prototyping transform your designs into sample in a fast and cost-effective way. With rapid prototyping, you can speed up process, which is essential for your project.

2. Save cost: Small-volume prototyping runs help to minimize costly design flaws.

3. Save time: rapid prototyping saves time by eliminating the need for setup and tooling

4. Multiple options: You can create a range of prototypes with different colors, various surface textures and surface treatment

5. Refine the parts: By utilizing iterative rapid prototyping, you can refine the product’s design and functionality before it is released for sale.

We are competitive because of our superior technology and team. We are constantly innovating and developing advanced methods to improve all manipulation aspects.

With various materials, Enze is the perfect choice for your prototyping project. Our extensive inventory includes nearly all types of materials, so you can get everything you need in our factory.

Our production capabilities are at a top level. Whether you need a single prototype or large-volume production, we offer rapid prototyping services to meet your requirements. There are no minimum order volumes so that we can cater to your needs.

At Enze, we understand the importance of quality and rapid lead times. We treat each order with precision and work to strict deadlines. We promise high-quality products and on-time delivery.

We guarantee an instant response to every customer request. You can get a free quote online.

Our efficient rapid prototyping system matches your budget. We strive to provide the best value for your investment.