Our Location

Product Name: Aluminum stamping products

Process: Aluminum stamping

Stamping machine Brand: Amada

Material: Aluminum

Surface treatment: sandblasting, painting

Machine: stamping machine

Price: Contact us for details

Application: Automotive, semiconductor, aerospace, agriculture, food, high-tech, machine tool, marine, medical, military, new energy, elevator.

Aluminum parts are popular due to the benefits below:

1. excellent surface finish

2. high strength-to-weight ratio

3. excellent thermal and electrical conductivity

4. low-temperature resistance

5. corrosion resistance.

However, aluminum is more expensive than steel, and welding may require additional processes. Despite these, aluminum is desirable for most sheet metal stamping applications due to its mechanical, physical, and chemical properties.

Metal stamping refers to techniques that transform aluminum sheet metal into any shape.

The primary methods used for stamping aluminum are:

Piercing aluminum involves punches and dies to create holes and notches in blank aluminum sheets.

A suitable metal stamping tool cuts a specific section from an aluminum sheet metal in blanking. Dies are commonly used for this and are ideal for removing the desired design from the workpiece. It is worth noting that blanking and punching aluminum are almost the same. However, the punching process removes the disliked part from the aluminum sheet.

Coining is an aluminum bending technique using a metal sheet between a punch and a die. Aluminum can also be transformed into L, V, or U shapes using aluminum stamping.

In embossing, a tooling system presses a pattern onto an aluminum surface, creating either a raised or recessed design.

Deep drawing forms depressions on aluminum. Tensional force pushes aluminum into the cavity. Fabricators minimize stretching.

You’ll need a metal stamping tool to add flange or flare to aluminum. You can do it once or multiple times. Another critical part is metal stamping operations.

Aluminum metal stamping offers four options:

Each technique allows cutting, punching, blanking, or punching aluminum, depending on the desired final product.

When selecting aluminum stamping blanks, it is crucial to take into account the following significant factors:

– Strength

– Practical usage, which includes aluminum parts and their applications

– Level of corrosion resistance

– Ease of machining and welding

– Degree of formability

– Any additional treatments required, such as heat treatment

– Availability of aluminum material

– Potential surface finishing options, such as painting or powder coating

Enze offers advanced technology and programming to handle aluminum stamping for your project. With our experienced team and quality control, your project is guaranteed to succeed with Enze Products’ assistance. We also offer other CNC machining services. Get in touch with us at admin@enze-mfg.com today to get a fast quote!

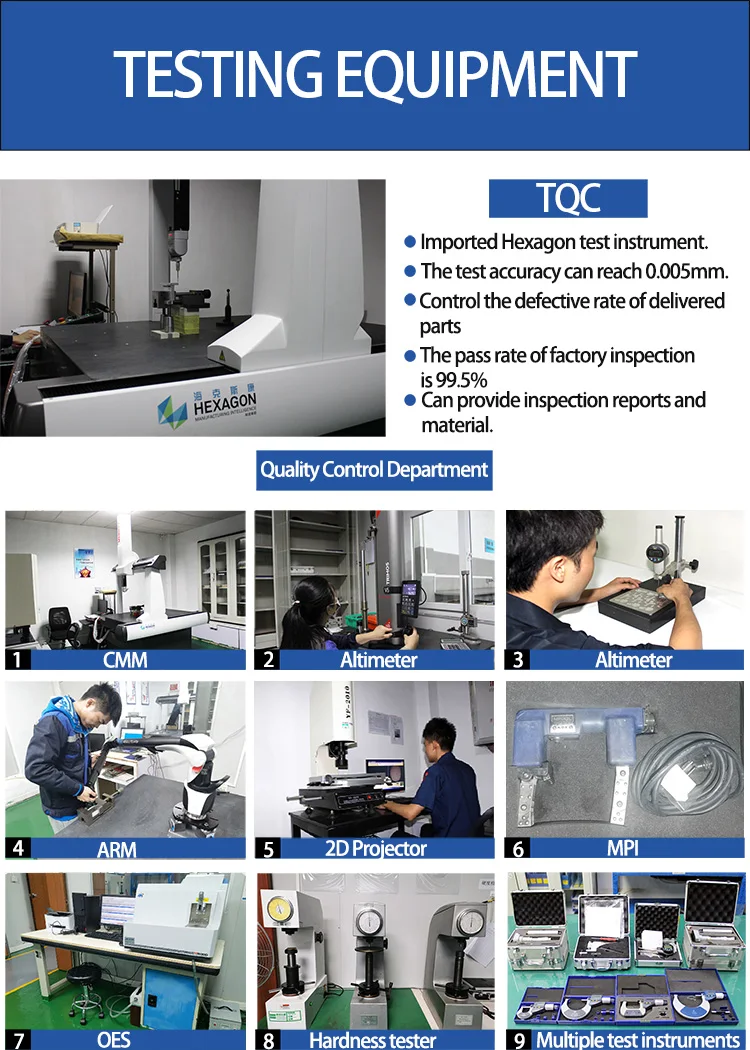

We have various testing equipment. Our experienced engineers ensure all the parts must 100% pass the testing.