Our Location

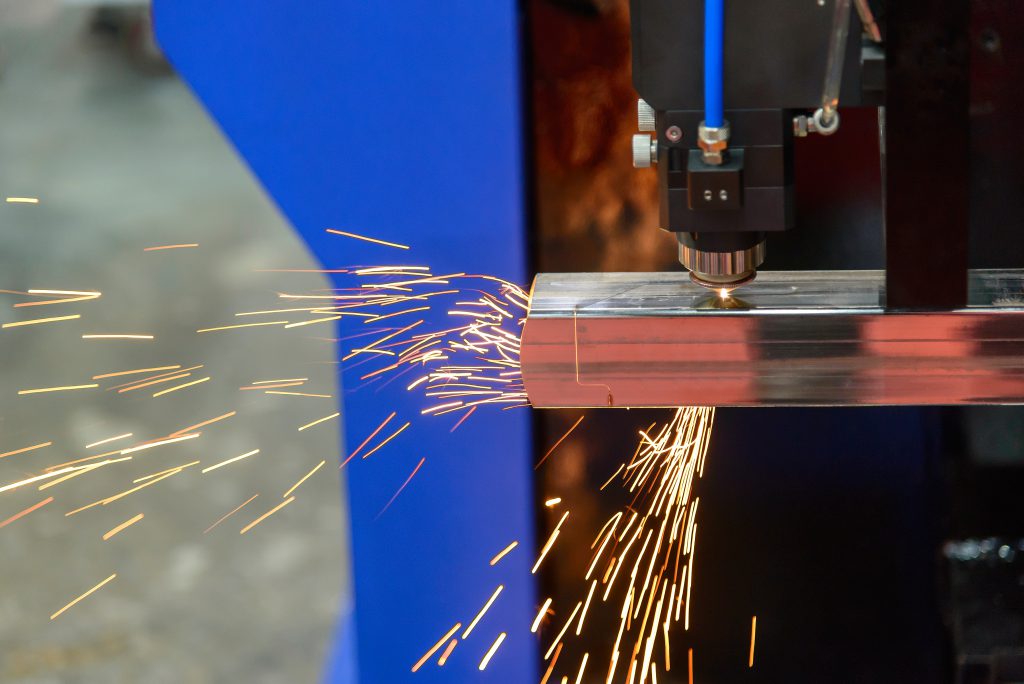

Part Name: Metal Laser Cutting Parts

Equipment brand: Trumpf

Material: Aluminium, Aluminium Alloy, Stainless Steel, Carbon Steel, Copper, Brass,etc

Processing: Laser Cutting

Surface Treatment: Polishing, Anodizing , Powder Coating, Plating, Silkscreen Printing, Sandblasting

Thickness:0.1mm~16mm

Processing range: T≤16mm, 6000*2000mm(max)

Supply Ability:10,000 pcs per month

Packaging Details:

1.Inside the bubble bag or air cushion film

2. outside the carton box

3.ordinary sea packaging with pallet

4. depends on clients’ request

Metal laser cutting materials include aluminum, steel, copper, and stainless steel.

Aluminum materials for laser cutting include 5052, 5083, 5754, 6060, 6061, 6082, and 7075

Steel materials for laser cutting include Q235, Q275, Q345, DC01, C45, and S355.

Stainless steel materials for laser cutting include 301, 302, 304, 316 and 316L

Sandblasting uses tiny beads to remove imperfections from a part’s surface, leaving a smooth finish. The recommended product size is 6-600 mm in height and width. The resulting texture is slightly grainy and uniform, matte, or satin-like.

The electrochemical cleaning process for steel parts improves the appearance and reduces corrosion.

Tumbling media removes sharp edges and burrs on machined parts. It may dull edges and is not recommended for fragile parts—it results in a smooth, matte appearance.

A clear coating that enhances corrosion resistance for 200 and 300 series and precipitation-hardened, corrosion-resistant steels by eliminating free iron from the surface.

Electroless nickel plating creates a uniform nickel coating that protects against corrosion, oxidation, and wear on irregular surfaces. It also provides a brighter appearance and can be treated with clear or gold chromate conversion coating/chem filming for added durability and corrosion resistance.

Chromate conversion coatings enhance corrosion resistance and conductivity and can be used as a base for paint. Type I is gold/brown; Type II is clear and doesn’t affect surface color.

Zinc plating deposits a thin layer of zinc on a metal object, creating a barrier that prevents rust and increases corrosion resistance.

Gold Plating offers good corrosion resistance and a bright appearance.

Silver provides high solderability and electrical conductivity.

Anodizing creates a protective layer on aluminum that is resistant to corrosion and abrasion. The layer can also be colored for an excellent finish.

Powder coating is a reliable, sturdy finish that shields metal surfaces, parts, and products from corrosion. It is important to note that while powder coating cannot protect surfaces that already have rust, it can prevent rust from forming if applied and maintained correctly.

We are a certified industry leader with an ISO 9001 license and offer cost-effective solutions for all project sizes. Our team delivers fast quote request turnarounds and works within your budget. Contact us at admin@enze-mfg.com for more information.