Our Location

Metal stamping is a cold-forming manufacturing process, it makes excellent use of dies and stamping presses in forming sheet metal into specific custom shapes. It is a complicated process that includes many metal-forming techniques, such as stamping, bending and piercing.

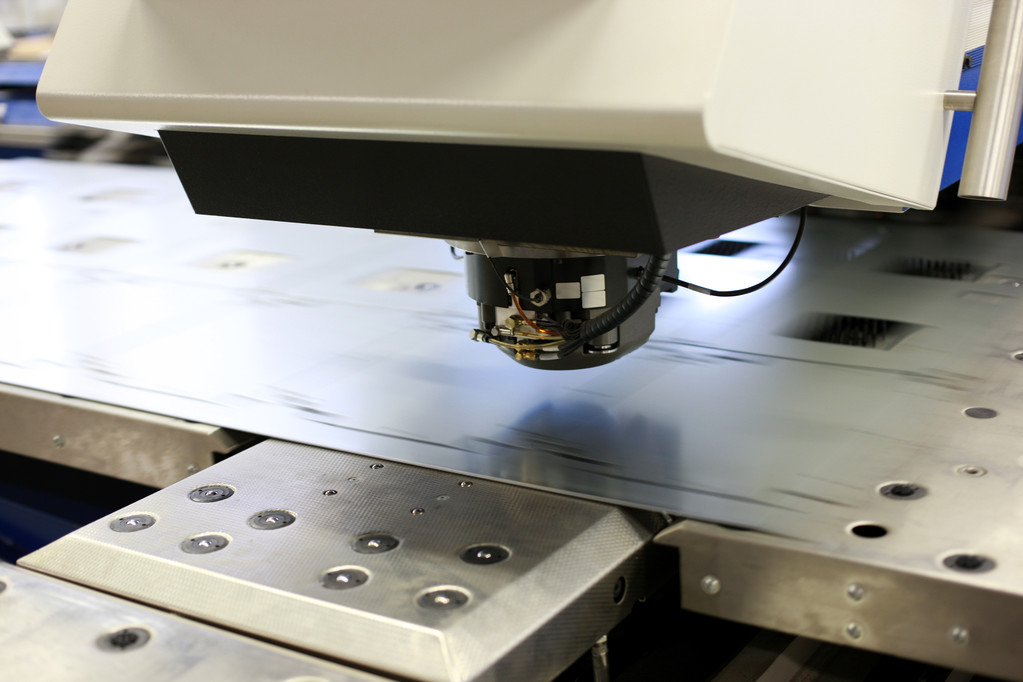

At Enze, we make metal stamping in an easy and fast way. To finish your order quickly, we provide various design advice and fast delivery. Furthermore, CNC milling, CNC turning and 5-axis CNC Machining Services are also available. Enze is your ideal choice as a one-stop factory.

Enze provides three main metal stamping processes: progressive die, deep-drawn stamping, and automotive metal stamping.

Progressive die stamping involves processing a metal strip through multiple stages to perform various operations on the part. The part is transported along the stock strip and cut out in the final station. It is a fast process with a limited amount of wasted material. Progressive die stamping is usually used to mass-produce parts and keep costs low. It is crucial to meet the highest standards of precision and durability.

Enze provides deep drawn stamping service, This process compresses the metal structure into a more crystalline form, resulting in rigid pieces. The outcome of this process is a strain-hardened component that is highly precise and has no seams or attached sections.

Automotive metal stamping is when a machine punches, bends and manipulates metal in an automatic feeding system. The technology enables the efficient manufacturing of precise and complex parts at scale.

Aluminum is a versatile material with a high strength-to-weight ratio, great formability, and good thermal and electrical conductivity. Those properties that make it an excellent choice for creating metal stampings.

At Enze,we can provide various aluminum.

Al6061 / Al6063 / Al6082 / Al7075 / Al5052 / A380

Copper has good strength, hardness, superior thermal and heat conductivity, and corrosion resistance. They are ideal material for many metal stamping projects,which are soft for products requiring strength and durability, that softness makes them easy to shape into desired forms.

C11000 / C12000 / C12000 / C360

Brass is an alloying consisting of both copper and zinc.It is low friction, has excellent electrical conductivity and has a golden appearance.

HPb63 / HPb62 / HPb61 / HPb59 / H59 / H68 / H80 / H90

Stainless steel stamped parts show numerous advantages in a wide variety of applications.With high strength, versatility & flexibility, better resistance to corrosion,durability,appealing appearance

SS201 / SS301 / SS303 / SS304 / SS316 / SS416

Strong and versatile, steel is one of the most common materials used in metal stamping.

It’s strong, cost-effective and easy to obtain,can be treated to enhance certain properties

Mild steel / Carbon steel / Q235 / Q275 / Q345 / 20# / 45#

Metal stamping surface treatment is creating and applying a layer or physical barrier to protect the metal before coating takes place, we offer several surface finishes that help improve functionality and aesthetics.

A smooth protective film is applied in the substrate through compressed air, producing powdered material that is melted later. It is usually used for appearance components, and various colors are available.

Passivation is a chemical process used to treat stainless steel and other alloys that removes the extra material from the surface of the metal using an acid solution to prevent rusting.

Anodizing improves corrosion resistance, enhancing wear resistance and hardness, and protecting the metal surface.

It is the process of coating stamped steel and iron parts by immersing them in a bath of molten zinc. Through this treatment, metal parts are most likely to be highly corrosion-resistant. The salt spry testing time could pass 1000 hours.

Electroplating refers to plating a metal onto the other by hydrolysis, mostly to prevent metal corrosion or for decorative purposes.

Oiled surface treatments protect the material from corrosion. Oils are one such treatment with a low cost. It benefits the post process.

From steel to aluminum, from zinc plating to powder painting. We have the capabilities to meet your needs, whatever material you require.

Enze has been focused on manufacturing metal stamping for many years. Our experienced team provides customers with the best service and support.

High Quality is always our first choice. You can get excellent quality parts in China through full inspection before delivery.

Our experienced team and advanced equipment assure you that we will produce your parts quickly without delay.

Contact us for inquiries at admin@enze-mfg.com.We’ll give you a fast offer immediately.

We have presses ranging from 10 to 65 tons.

Thickness: ± 0.008 mm( Cpk requirements)

Length: ± 0.015 mm( Cpk requirements)

Surface Flatness: 0.020mm

Material Hardness: ± 15 Hv

In standard operation, Enze works to +/- .005″. If tighter tolerances are required, we can hold +/- .001″

We can provide fast prototypes according to your specifications before production.

We design and develop the tooling in our factory.

1 to 2 weeks in general, depending on the types and complexity of the die.

Generally, tooling’s proprietary ownership is on the buyer’s side if paid by customers.

After tooling life ends, we are responsible for new tooling development and maintenance.