Our Location

Are you looking for “mold makers near me”? Enze is known as the best mold maker in China. We offer various mold making solutions and have helped thousands of customers design parts suitable for processing using CNC machining, injection molding, forging, and sheet metal fabrication. Whatever you need, prototype dies for short-run production or mass production molds for millions of shots, Enze can handle them smoothly with a full product R&D service at a low cost.

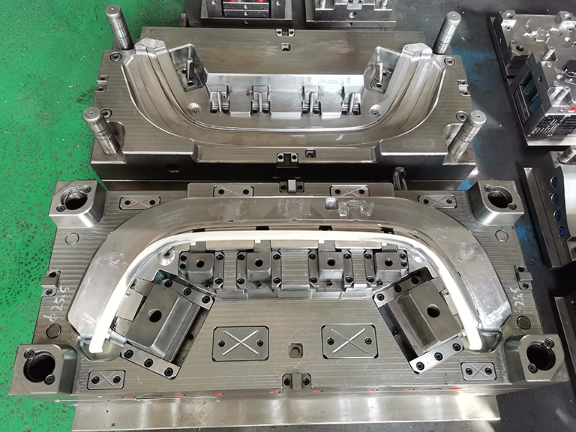

Mold making is essential to various manufacturing processes, requiring a high level of expertise and experience. Although cases are different, a typical order for a set of molds goes like this:

The Meeting is to discuss the requirements of production molds and solve related problems, including mold material, functionality, product appearance, application, inspection standards, etc.

Our process uses predictive modeling software to determine how the molten material will behave when it enters the mold. It helps us establish mold design specifications that complete the tasks of high quality, low cost, and fast lead time.

Process and manufacture according to the production plan using high-quality CNC machining equipment

It’s crucial to develop the T1 sample to see the custom part’s function and appearance

Check the shape, size, color, surface and discuss the results of the finished part with the client, review the mold design and make any adjustments according to the customer’s requirements.

Start in small batches for the first production according to the customer’s requirements. Then, mass production according to the injection molding process.

We guarantee that the mold will maintain its appearance during packaging, our workers will stack it on pallets, and delivery will only occur after client approval.

As a high-quality mold maker in China, Enze Machine’s mold-making partners can quickly make sheet metal molds. We can provide customers with high quality in a very short production time.

Injection molding is a manufacturing process used to produce parts by injecting material into a mold.

The process of die-casting mold enables efficient mass production of metal products and components. We can handle die casting and other services using these molds to provide you with prototypes and finished parts.

We can provide a fast DFM (design for manufacturability) report before mass production, which helps you to identify any features that may pose challenges during the molding process.

We reduce your product development cycle by weeks and bridge to production with molded parts within days. Some molding orders can ship in as fast as one day.

We offer a wide range of molds, so you don’t have to split your projects; send all projects to us, and we’ll ensure you finish them together quickly.

Enze work with you throughout your project to assist you in quickly moving from prototyping to production.

Turnaround time is essential to our customers. Our facility and machining capabilities allow us to build molds quickly, whatever the material or finish, which means moldings are available fast.

.

Mold-making is a manufacturing process to create duplicates of three-dimensional models or objects.

The time it takes to create molds varies depending on complexity and chosen process, ranging from days to weeks.

We offer mold design services based on customer’s requests. Also, we make recommendations for changes in design.

All molds and products are manufactured in our factory—100% in China.

Mold designs should avoid wall thickness, sharp tips, and other features that restrict material flow.

It depends on the customer’s requirements. We recommend our customers to use Polyurethane and Polyester Resins.

Buyers own the mold if paid by them.

After mold life ends, we are responsible for new tooling development and maintenance.