Our Location

Are you looking for a top CNC milling supplier in China? Enze provides precise and reliable milling services to meet all your machining needs. Contact us to see how we can help you!

CNC milling is a CNC machining process using CNC milling machines to manufacture precise and complex parts for various industries. We got 3-axis, 4-axis, and 5-axis CNC milling centers with high-precision equipment and experienced teams. Enze is an ISO9001:2015 certified company that provides CNC milling services to customers across different sectors all over the world.

At Enze, we provide a wide range of CNC milling services to meet the needs of our customers. Our services include:

A profitable and efficient solution to your CNC milling needs! This type of milling involves the movement of the cutting tool along three axes to create a precise shape or design.

Get more complex CNC milled parts with our 4-axis CNC milling. With 4-axis milling, the cutting tool can move along four axes to create more complex shapes and designs.

5-axis CNC milling machines can produce complex parts without additional setups. We can achieve higher cutting speeds while reducing pressure on the cutter, resulting in superior surface finishes for rapid prototypes and low-volume production parts.

Our experienced teams can design the best processing technology and select the fitting tool as per your drawings to mill and obtain a smooth surface quickly, maintain strict tolerances, and ensure the highest quality output. We regularly maintain and calibrate our machines to ensure optimal performance.

Why aluminum for CNC machining and CNC milling parts is a good choice?

Al6061 / Al6063 / Al6082 / Al7075/ Al5052 / A380.

Mild steel/Carbon steel / 4140 / 4340 / Q235 / Q275 / Q345B / 20# / 45#.

SS201 / SS301 / SS303 / SS304 / SS316 / SS416.

Why choose brass and copper for CNC machining and CNC milling parts?

C11000 / C12000 / C12000 / C36000, etc. and Brass HPb63 / HPb62 / HPb61 / HPb59 / H59 / H68 / H80 / H90.

This material has exceptional resistance to corrosion, chemicals, and extreme temperatures.

TA0 / TA1 / TA2 / TC4 / TB5

Why plastic for CNC machining and CNC milling parts is a good choice?

PET / PVC / ABS / PC / PE / PTFE / POM / PMMA / Nylon / PP / Peek.

Sandblasting, Powder Coating, Electroplating, Polishing, Brushing, Painting, hot dip galvanizing, oiled surface

| Max. Components Dia. | Metal parts | Plastic parts |

| 3-axis | 1500mm(59.055″) | 1500mm(59.055″) |

| 4-axis | 350mm(13.779″) | 350mm(13.779″) |

| 5-axis | 500mm(19.685″) | 500mm(19.685″) |

| Min. Components Dia. | Metal parts | Plastic parts |

| 3-axis | 0.3mm | 0.3mm |

| 4-axis | 0.3mm | 0.3mm |

| 5-axis | 0.3mm | 0.3mm |

Quality and precision in CNC milling are critical. For this reason, we implement a thorough quality control procedure. We ensure that all the parts we produce meet your specifications. Our process for quality control includes:

A thorough inspection is conducted to guarantee adherence to superior quality and consistency standards of all raw materials used before milling.

We regularly calibrate our machines and gauges to ensure they are in good working condition and can produce accurate results.

We inspect components at every stage of the milling process to guarantee they meet your specific requirements.

Before delivery, we will inspect every part to ensure it meets your quality and precision requirements for shipping.

Enze offers various CNC machining tolerances to meet your unique design requirements. Based on your product’s geometry and material, we can accommodate standard thread sizes, machine custom treads, and reach tolerances of up to ± 0.005mm(metal) / ±0.05mm(plastic)

We have achieved high precision with tight tolerances ranging from +/- 0.001″ to 0.005″.

Our production process ensures precise and repeatable results that meet specifications. It saves valuable time and reduces production costs significantly.

Enze provides the latest CNC machines to produce high-precision and fast-milling parts; the fastest time is within 24 hours.

Enze can provide a wide range of customized CNC milling parts to meet your needs. Our experienced teams design the milling process and select the appropriate tool based on your files, then do the milling fast while obtaining an ideal processing surface. By maintaining our strict tolerances, we ensure you the best quality.

Choose from over 60 metal and plastic materials with various surface finishes.

Our superior milling machines and optimized milling workflow ensure you can quickly get a physical copy of your digital design.

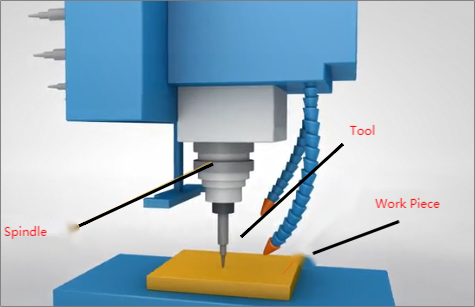

CNC milling is cutting metal material or plastic into final precision parts using different axis milling processes. The 3-axis, 4-axis, and 5-axis milling machines realize a versatile, accurate, and repeatable CNC milling process for producing various features and complex geometries.

The CNC milling process starts with designers using CAD software to create digital parts. After completing your 3D CAD files, you can conveniently submit them online to receive an instant offer.

1. Designing a 3D model with CAD software

2. Convert the CAD model into the CNC machine program

3. Start the CNC machining process through the interface or control panel

4. Block material from the workpiece to get the desired shapes

5. Conduct the CNC milling operation with high precision

CNC milling machines are usually defined according to their number of axes. More axes mean the ability to manufacture complex parts and create cutting angles is enhanced and strengthened.

3-axis: CNC milling cutters usually have three axes, which means the spindle and the cutting tool can drive along the X, Y, and Z axes. However, if the cutting tool cannot reach a specific area of the part, the part itself must be taken out and rotated manually.

4-axis: With 4-axis milling, the cutting tool can move along four axes to create more complex shapes and designs.

5-axis: The process of 5-axis milling uses high-speed cutting tools and machines to produce complex parts efficiently.

CNC milling machines can use various tools for different types of cutting, such as end mills, face milling cutters, slab milling cutters, fly cutters, ball cutters, hollow cutters, and roughing end mills.

Yes. Enze is the best choice for 5-axis machine manufacturing. Our machines process complex parts and acquire parts that demand close tolerances.

As a top CNC milling parts manufacturer in China, Enze operates advanced machines and offers various materials and surface finishes. We provide many CNC milling services to meet all customer needs.

Both 2D and 3D options are available.

There are no specific minimum requirements.

We have ISO 9001 quality management system certificate that ensures our work conforms to certain quality standards. If specific tolerances are required, please attach a drawing with relevant information.

Turnaround time for CNC milling parts varies based on complexity, quantity, and customer requirements. Typically, it takes 1 to 2 weeks, but expedited options may be available.

If you need an offer, please contact me at admin@enze-mfg.com