Our Location

Machine: CNC Bending machine

CNC machine Brand: Doosan

Process: CNC bending

Material: Steel, stainless steel, aluminum, carbon steel

Surface treatment: Zinc plating, polishing, Anodizing, Powder coating, Sandblasting, Hot-dip galvanizing

Price: Contact us for details

CNC bending involves using computer numerically controlled machines to bend sheet metal work accurately. At Enze, we utilize various manufacturing techniques, and CNC bending is one of them. Because of the Advanced technology, our engineers can use large industrial machines to bend sheet metal of any length, ranging from just a few millimeters to several meters.

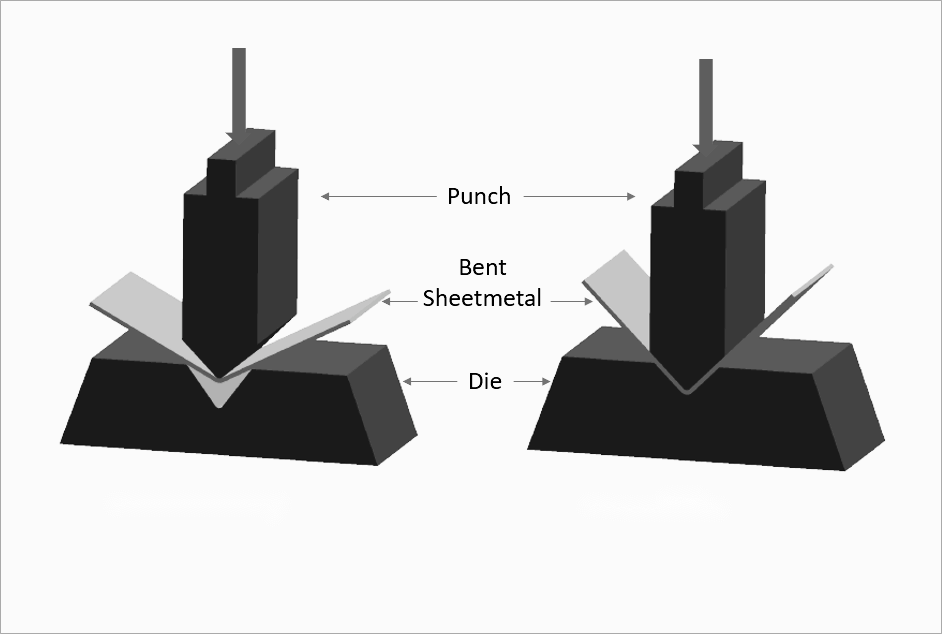

There are two available CNC bending Techniques: down forming and up forming. Both produce the same results, which provide engineers with limitless design options. CNC press brakes handle various sheet metal components and determine the length of the piece that can be bent. The material’s thickness is aligned with the material tensile strength and tonnage the machine can handle. The bigger the lower V block opening, the larger the sheet metal gauge engineers can use to bend the metal.

When working on a CNC bending project, specific design considerations and size can affect the result of the workpiece. The bend line indicates the start and end of a bend. The bend radius is the distance from the axis of the bend to the bend’s interior surface. The most commonly used radius is 90°, and to save cost and do it more efficiently, Metal Works can bend up or down on the same plane.

To get the perfect radius and angle of bend, parts often need to be overbent due to residual stress in the material following bending, known as spring back. The minimum bend radius in most applications should equal the material thickness to prevent fracturing, although the value depends on the specific material and application.

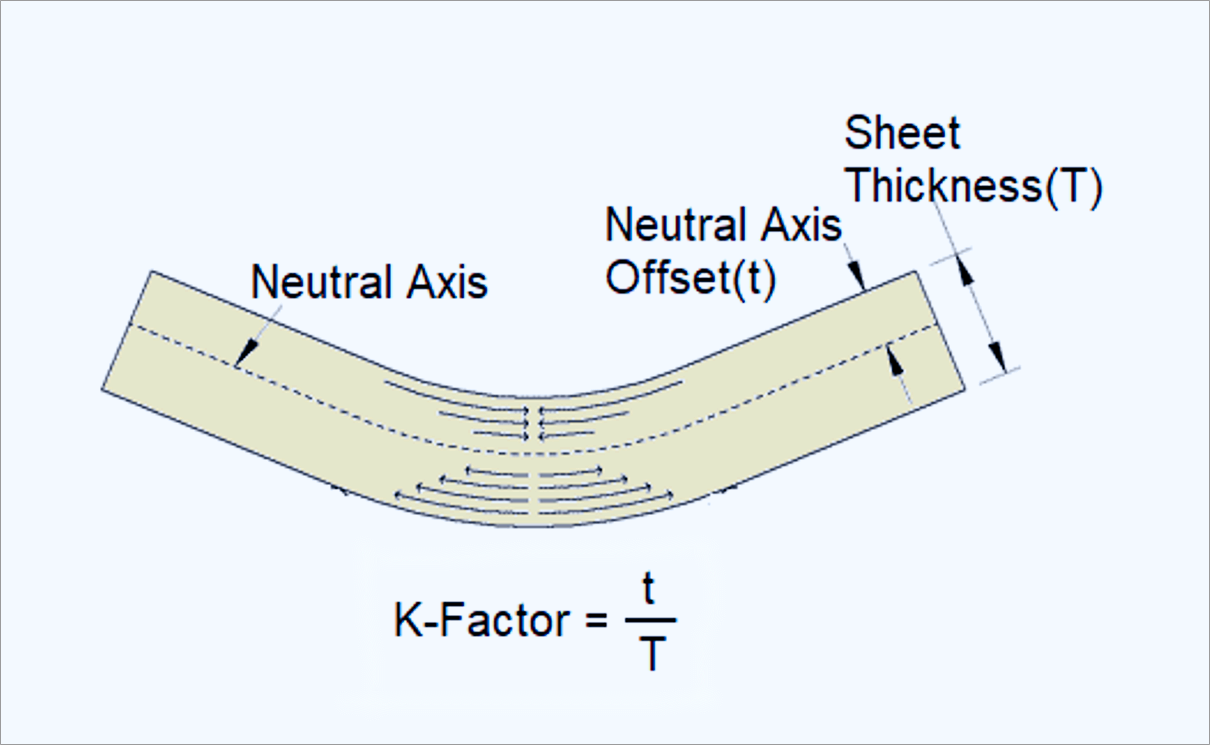

The bend angle is measured between the bent flange’s two legs. It, along with sheet thickness, determines the outside bend radius. The neutral axis is the part of the sheet that stays at a constant length during bending.

The K-factor defines the neutral axis’s position relative to the bending material. It is calculated by dividing the neutral axis (T) by the sheet thickness (t). The K-factor value is typically higher than 0.25 but below 0.5.

The bend allowance is the length between the bend lines. Adding it to the flange lengths gives the total flat length. Bend reliefs are used when a bend extends on an edge. The relief should not be deeper than the bend radius and material thickness, and a relief notch is necessary to prevent tearing during bending.

To prevent part deformation, the bending height (H) should be at least four times the thickness (t) of the sheet plus the bend radius (r). The formula for calculating the bend height is H = 4t + r. Additionally, be cautious when bending panels near holes, as it can lead to hole deformation.

In the manufacturing industry, time is critical. Components not produced to the highest standard become unusable, leading to more material usage and extended deadlines. The CNC bending process offers significant benefits to OEM suppliers, which can be passed on to customers. These benefits include:

Cost Saving: The CNC bending process is automated, making it one of the most efficient services compared to manual services like welding. Each process requires only one machine, reducing the need for multiple steps across different machines. Automation also reduces laborers in the production process, with their primary function being to feed metal sheets or tubes to the machine, minimizing human error and inaccurate components. Besides the initial investment costs, maintaining a CNC machine doesn’t require significant capital. Reducing the number of laborers also results in lower labor costs.

Time-Saving: One of the significant benefits of automated machines in manufacturing is the amount of time saved in the production process. CNC fabrication speeds up the production process by reducing the need for manual labor. Additionally, the improved accuracy and consistency of CNC machinery eliminates the need for fixes that would otherwise need to be accomplished manually.

Consistency and Accuracy: CNC machines are ideal for producing precise components that meet customers’ increasing demands. Mathematical precision in the manufacturing process guarantees the consistency and accuracy of the components’ quality.

CNC bending significantly benefits various industries, including aerospace, agriculture, automotive, medical, and new energy. The process saves time and labor costs while ensuring high-quality components.

1. Aerospace. Aircraft endure significant stress and strain, making safety and high-performance components crucial in the aerospace industry.

2. Automotive. Various components for automotive parts require significant amounts of sheet and tube metal to withstand high pressure and last the vehicle’s lifetime, similar to the aerospace industry.

3. Medical. Medical tools often require precise components that can only be mass-produced using machines capable of manipulating tiny pieces of metal.

4. New energy. CNC bending is an essential process for producing complex solar-related components. The technology is versatile and can handle a range of materials when making parts effectively.

Therefore, it is essential to partner with a CNC machining supplier with the necessary capabilities for the CNC bending process, given its many potential uses.

Enze Metal Products has advanced technology and programming to handle CNC bending for your project. With our experienced team and quality control, your project is guaranteed to succeed with Enze Products’ assistance. We also offer prototype production services and other CNC machining services. Get in touch with us at admin@enze-mfg.com today to request a quote!