Our Location

Process: Anodizing

Material: Aluminum or alloy aluminum

Surface Cleaning: You can use alkaline or acid cleaners to eliminate grease and surface dirt effectively.

Color: Clear, yellow, black, grey, red, silver, blue, gold, etc.

Features: Matte finish, Smooth

Whether CNC machined or sheet metal fabricated, aluminum parts can be anodized. The electrochemical reactions involved in the process may seem complex, but the process is simple and cost-effective. Anodization is a widely used option in various industries.

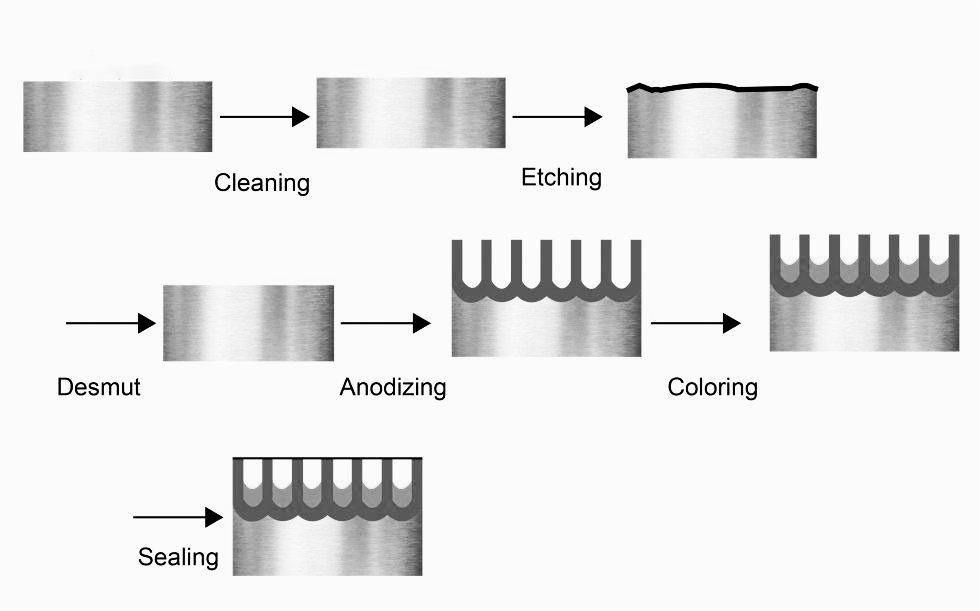

The main anodizing process steps as belows:

Cleaning the aluminum part before anodization is crucial to remove any impurities hindering the process.

Before treatment, etching and brightening are necessary steps.

Aluminum is dipped in an acid electrolyte solution. An electrical current passed through it. A piece of aluminum is placed in an anodizing tank with a cathode. The electrolyte solution releases oxygen ions that combine with the aluminum atoms, creating a protective layer. Essentially, anodizing is a process of carefully controlled oxidation, which enhances a natural phenomenon.

Four coloring methods exist for anodic film: Electrolytic Coloring, Integral Coloring, Organic Dyeing, and Interference Coloring. After the anodic film is colored, it seals, closes the pores, and provides staining resistance.

It’s essential to understand the different aluminum types used in the process. There are three main types of anodizing, each producing unique functional and aesthetic properties.

The chromic acid anodizing process involves using chromic acid to create a thin coating on metal parts. This coating is typically up to 0.0001 inches thick. Despite being the most delicate anodizing coating, it provides metal parts with improved corrosion resistance. It cannot be used for color anodizing as it appears light grey and absorbs less color when dyed. This type of anodizing is primarily used for non-decorative purposes, such as making non-reflective surfaces in the aerospace industry or components for precision machines. It is often dyed black.

This type of anodizing is an environmentally friendly alternative to chromic acid anodizing and is covered by MIL-A-8625. It is commonly used for corrosion protection and paint adhesion and is more energy-efficient than chromic anodizing.

Sulfuric acid type anodizing is the most commonly used method, known as regular anodizing. It has the most widely applied solution containing sulfuric acid, which provides a moderately thick coating. Additionally, it’s a much harder finish than chromic anodize.

The sulfuric acid anodizing process employs sulfuric acid instead of chromic acid, resulting in a marginally thicker layer on the aluminum component. This type of anodize has a thickness ranging from 0.0002 to 0.001 inches and is more suitable for dyeing parts.

Hardcoat anodizing, also called sulfuric acid hard anodizing, involves using an electrolyte based on sulfuric acid to produce a denser and thicker aluminum oxide coating. This process is known for creating parts with excellent abrasion resistance and can be dyed in various colors. However, there may be better choices for components with very tight tolerances.

Bright dip anodizing produces a shiny, reflective surface. The hardness of the aluminum oxide determines the brightness of the coating. This technique is commonly used for manufacturing car components and flashlights.

The titanium anodizing process involves the artificial growth of titanium oxides on top of a titanium base metal using electrolysis. Professionals typically dye aluminum to achieve the desired color due to the messy process. Unlike aluminum, titanium does not require dyeing due to its oxide film, which refracts light differently than most other metal oxides. The oxide film reflects light of a specific wavelength based on its thickness. By adjusting the voltage during the anodization process, the color of the titanium surface can be controlled, allowing it to be anodized to virtually any color one can imagine.

Our anodizing treatment is the only one in the metal industry that meets all the factors necessary for high-performance aluminum treatment. As a unique surface finishing service, it possesses many desirable characteristics:

Most anodized products have a long service life and offer economic benefits through maintenance and operation. Anodizing is a process where the surface of aluminum is oxidized to form a layer of aluminum oxide, which is integral to the metal and provides excellent adhesion and corrosion resistance.

The anode coating has excellent UV stability, does not peel, and is reusable.

The surface hardly shows any scars or wear from manufacturing, handling, installation, frequent cleaning, or dirt accumulation. Simply rinsing with water or cleaning with mild soap can restore the anodized surface to its original look. In the case of more rigid deposits, mild abrasive cleaners can be employed.

Anodizing enhances aluminum’s metallic appearance by increasing luster and color stability while reducing color changes in other finishes.

The lower initial processing and maintenance costs can result in more excellent long-term value.

The anodized finish is a stable, non-decomposing, and non-toxic coating. Anodizing extends natural oxide formation and produces no harmful by-products.

Anodizing is an electrolytic oxidation process that transforms the surface of aluminum and its alloys into a protective, decorative, and functional oxide film.

Anodizing creates a protective layer on aluminum that is resistant to corrosion and abrasion. The layer can also be colored for an excellent finish.

Anodizing is an environmentally friendly and safe technology that does not harm humans or the environment.

When working with anodizing solutions, the temperature has a direct impact on the conductivity of the bath. If the temperature increases, the conductivity also increases, which can cause burning on critical parts and make the anodizing solution more aggressive. This may result in the oxide becoming soft or even dissolving. Maintaining a stable temperature is essential to achieve consistent anodizing results. Our systems are designed to hold temperatures within a +/- 2° Fahrenheit range.

When trying to chill an anodizing tank, it’s essential to prioritize tank space and consistent cooling. Although an in-tank coil can do the job, it’s reliant on air agitation to distribute the cooling effect evenly throughout the whole tank. The less air you use, the less effective the cooling response will be. Enze takes a different approach by using an external heat exchanger and pumps to distribute cooling evenly throughout the anodizing tank. This method allows us to maintain tighter temperature parameters than cooling coils.

Before anodizing, it’s crucial to polish the base material for a shiny finish.

Steel cannot be anodized because the process baths used to anodize aluminum would corrode and dissolve steel parts.

Many applications for anodizing include medical products, automotive parts, lighting fixtures, new energy equipment, and elevator components.

The anodizing process workers require a few days to plan and execute. But, the anodizing processing only takes a few hours.