Our Location

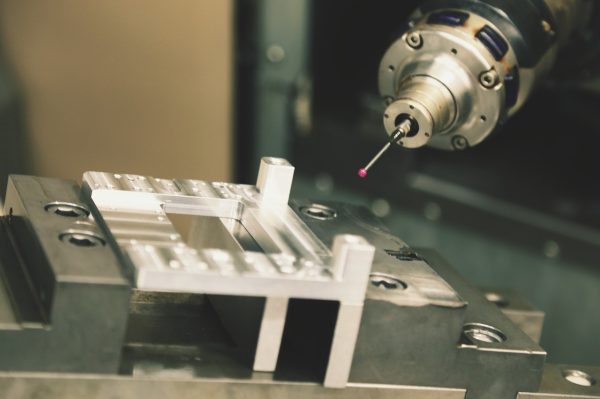

Enze provides customers with a reliable one-stop CNC machining service. We use 3-axis, 4-axis, and 5-axis CNC machines to manufacture parts from various plastics and metals. Whether you need prototypes or production parts machining, our CNC service will be your best choice. You can get more competitive prices at higher quantities with machined production parts. Request your online quote to complete your machining parts as quickly as one day!

As one of China’s best CNC machining components manufacturers, Enze operates over 100 sets of 3, 4, and 5-axis CNC machines and offers 200+ materials and surface finishes, guaranteeing quick turnaround and quality of one-off prototypes and production parts.

Fast delivery time and delivery are our promised Range of materials, which offers 200+ types of materials.

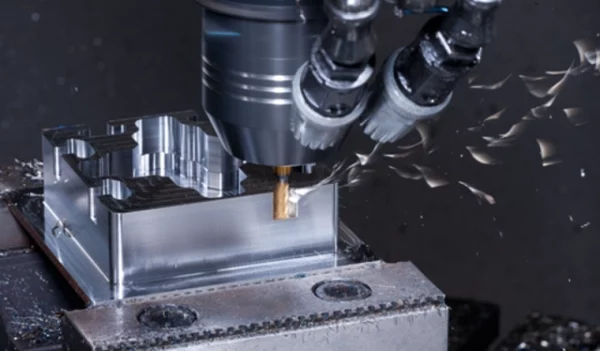

CNC milling refers to manufacturing that cuts solid plastic and metal material into final precision parts using 3-axis, 4-axis, and 5-axis CNC milling processes. It removes material from bulk using tools to cut/drill a workpiece. CNC Milling can produce parts with high accuracy at a high speed.

CNC turning refers to a manufacturing process in which a stationary cutting tool removes material from bulk by rotating the workpiece. High accuracy and repeatability can be completed under the control of computer instructions for moving the machinery.CNC Turning is excellent for the processing of cylindrical parts and is capable of producing high-quality parts cost-effectively.

5-axis machining is a sophisticated cutting method that simultaneously moves a tool or part in five axes. Capable of cutting in the X, Y, Z, A, and B axes, 5-axis machines can produce parts with incredible geometries and complexity because the tool head can move in all three directions and rotate around the region on two different axes.

5-axis Machining types,, including Indexed 5-axis, Continuous 5-axis, and 5-axis Mill-Turning CNC Center

Aluminum is an ideal versatile material for CNC machining.

Enze can provide almost all CNC machining aluminum.

Grade: Al1024 /Al6060 /Al6061 / Al6063 / Al6082 / Al7075 / Al5052

Copper has good strength, hardness, superior thermal and heat conductivity, and corrosion resistance. It is used widely for its functionality and aesthetic.

Grade: T1、T2、T3、TU0、TU1、TU2、TP1、TP2.

Brass is an alloying consisting of both copper and zinc. It is low friction, has excellent electrical conductivity, and has a golden appearance.

Grade: HPb63 / HPb62 / HPb61 / HPb59 / H59 / H68 / H80 / H90

Stainless Steel shows numerous advantages in a wide range of applications. With high strength, versatility, flexibility, better resistance to corrosion, durability, appealing appearance

Grade: SS201 / SS301 / SS303 / SS304 / SS316 / SS416

With low costs and high functionality features, Steel is always a good choice. However, it will oxidize over time, so a surface finish is required to protect it.

At Enze, we have skilled workers who can manage all your steel CNC machining requirements.

Grade: Mild steel / Carbon steel / Q235 / Q275 / Q345 / 20# / 45#

Titanium is the ideal metal for demanding applications. Enze provides multiple options for various manufacturing processes of titanium components, including milling, turning, and drilling.

Grade: TA0 / TA1 / TA2 / TC4 / TB5

At Enze, we turn plastics into parts through various methods, including CNC machining, CNC turning, CNC milling, and 5-axis CNC machining.

Our CNC machining capabilities include many materials.

|

|

At Enze, we offer various surface finishes that help improve functionality and aesthetics.

As machined finish means without any surface treatment processing methods, cutter marks from the CNC Machining process will be visible, which can be completed quickly and cost-saving.

Powder coating is a finishing process that creates a protective layer by covering metal parts with dry powder, which is used for appearance parts, and various colors are available.

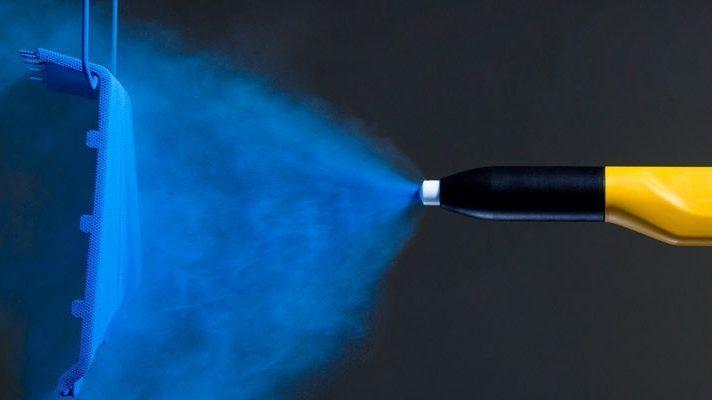

Sandblasting, also called abrasive blasting or dustless blasting, is a surface finishing process that uses air pressure to force small, abrasive particles at a surface to quickly remove materials from the object to prepare its surface for coating.

Shotblasting is a surface treatment process that removes debris and impurities from different surfaces using an abrasive.

Passivation is a surface finishing for stainless steel and other alloys that removes the extra material using acid or other chemicals to prevent rust.

Logo printing transfers a logo design onto a physical surface such as paper, fabric, or plastic. We can provide Laser marking silkscreen.

Anodizing improves corrosion resistance, enhancing wear and hardness and protecting the metal surface.

Polishing refers to creating a clean and Mirror-like surface by rubbing or using chemical interference.

Electroplating refers to plating a metal onto the other by hydrolysis, mainly to prevent metal corrosion or for decorative purposes.

Oiled surface treatments protect the material from corrosion. Oils are one such treatment with a low cost.

| Type | Tolerance (mm) |

| CNC Milling | Metal ±0.005 / Plastic ±0.05 |

| CNC Turning | Metal ±0.005 / Plastic ±0.05 |

| CNC Grinding | Metal ±0.005 / Plastic ±0.05 |

| Max Roughness | Ra0.1 |

With precision CNC machining services, Enze is your ideal supplier for creating precision machined components. Our standard CNC machining tolerances are ISO 2768-f(Metal) and ISO 2768-m(Plastic). Please notify us if you need a specific tolerance; we will achieve to meet your requirements on your drawing.

| CNC Milling | CNC Turning | |

| Maximum Dia. | 138in (3500mm) | 99in (2500mm) |

| Minimum Dia. | 0.003in (0.1mm) | 0.003in (0.1mm) |

▼ Advanced CNC machines and experienced team.

▼ Consistent High Quality. Full Inspection Before Delivery

▼ Best Price with Excellent Quality you can get in China

▼ Full Series of Materials – Various alternatives of possible combinations of materials and finishes for your order.

▼ Fast Lead Time. Our team and equipments assure to accelerate the production of your prototypes or parts.

▼ 24/7 Engineering Support/24 Hours Online Service

Our CNC machining center has more than 100 advanced equipment, which is equipped with 3-axis, 4-axis, and 5-axis CNC machines, enables us to design and efficiently manufacture parts, these machines are capable of high accuracy engineering and high production capacity.

CNC machining uses computerized instructions to perform manufacturing tasks through a subtractive process accurately. CNC is an abbreviation that refers to computer numerical control. Various complex machines such as grinders, lathes, mills, and routers can be controlled. With CNC machining, single prompts can accomplish three-dimensional cutting tasks. It uses various sharp cutting tools through the computer to precisely control multiple shapes and sizes to achieve the final design. The benefits of CNC machines include excellent positioning accuracy and high repeatability, so you get consistent results every time. CNC machining is appropriate for quickly creating prototypes and producing large volumes of products.

The CNC machining process has various capabilities and operations. However, the fundamental principles are the same throughout all processes. The primary CNC machining stages are as follows:

1. CAD model designing

2, CAD file converting

3, CNC machine setup

4, CNC machining operation execution

Benefits of CNC machining include excellent positioning accuracy and high repeatability. So, we always get consistent results. Furthermore, CNC machining can also use various materials, including stainless steel, aluminum, copper/brass, titanium, and plastics. That is why CNC machining is so widespread.

The most common mechanical CNC machining operations include:

1, CNC Drilling

2, CNC Milling

3, CNC Turning

The CNC machining process is widely used for various engineering materials, including aluminum, copper, stainless steel, titanium, and alloys, and we also can machining plastics materials such as PEEK, PTFE, and Nylon.

Many elements affect the costs, including materials, surface treatment, machining time, quantity, and machining difficulty. To quote correctly, you can provide us with the required details; we will send you a manufacturing analysis and quotation soon.

Enze provides global industries with CNC machining Services. Our high-quality CNC machining services include 5-axis machining, CNC milling machining, and CNC turning. Our parts are widely used in the following industries:

2D&3D are both available.

Yes,they are available.Enze is your best choice for 5-axis machine manufacturer with top precision to help you reduce cost, process complex parts, and acquire parts that demand close tolerances.

We have ISO 9001 quality management system certificate that ensures our work conforms to certain quality standards. If specific tolerances are required, please attach a drawing with relevant information.

30 to 40 days in general, it depends on the part‘s size, technical requirements, and quantity.

Obviously we can sign NDA before you send the drawing.

Please send drawings with product details, including the material, size, tolerance, surface finish, and other requirements, we will give you feedback within 24 hours. Contact us today to get a fast quotation.