Our Location

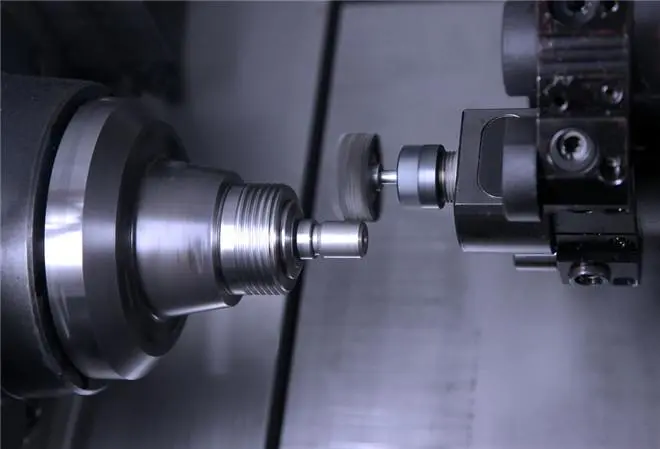

After metal processing, the surface shows visible tool markings. Proper surface finishing can enhance surface appearance, roughness, wear resistance, and functionality of CNC machined parts.

Since the machined finish requires no post-processing, it is a convenient option. It refers to keeping the surface in a machined state. As-machined finishes are ideal for parts that require precise tolerances. The typical surface roughness for as-machined materials is 3.2 μm (125 μin). Additional polishing and smoothing can be performed if the roughness is not within the required range, which improves surface quality and reduces roughness for better visual appearance.

1, Supporting any material.

2, The advantages of an as-machined finish are consistent results among various units and the strictest dimensional tolerances.

3, An as-machined finish does not require additional processing, so it is cost-effective and appropriate for prototype development projects. It is cost-effective and suitable for prototype development.

This surface finish may leave visible tool marks on your final part and lacks a protective coating, which quickly causes rust.

1. Simple Geometry: Simplify the part geometry to make it easier to machine, avoiding complex shapes and tight tolerances whenever possible.

2. Optimized Tools and Toolpaths: Optimize tools and toolpaths by minimizing vibrations, sharp tools, and selecting toolpaths that reduce tool engagement.

3. Machinable Materials: It is essential to choose materials known for their machinability and surface finish characteristics.

Specifying a surface finish “as machined” is crucial since it determines the quality and texture of the workpiece’s surface right after CNC machining. It helps establish expectations for the surface finish without further post-processing, which is particularly important for parts with strict functional or aesthetic requirements.

Achieving the desired surface finish when several factors can influence machining. These include the sharpness of the cutting tool, the material being machined, the accuracy and rigidity of the CNC machine, as well as feed rates and cutting speeds. The operator’s skill and choice of machining parameters also play a crucial role in obtaining the desired surface finish.

Different types of machining finishes are available, apart from the As-Machined Finish. These include Textured Finish, Smooth Finish, Mirror Finish, and Anodized Finish.

On the other hand, a Textured Finish is required for parts that need a textured surface for grip, aesthetics, or other functional reasons. Processes like knurling or bead blasting can be used to achieve this finish.

A Smooth Finish is obtained through processes like grinding or honing, which result in a very fine surface texture. It’s suitable for parts that require a smooth surface for aesthetic or functional reasons.

For metals like aluminum, an Anodized Finish can be created through an anodizing process, which creates a protective oxide layer on the surface. It not only provides protection but can also add color to the part.

Mirror Finish is another type of finish that is highly polished and reflects light, similar to a mirror. It’s obtained through extensive polishing and is often used for decorative parts.

Choosing the right machining finish is crucial. It’s better to consult a machining expert for the most suitable finish based on the part’s intended use, material, and design specifications.