Our Location

CNC machining is creating molds for injection that offer consistent and repeatable results. CNC machines are fast and accurate, producing more precise machined products. Precision is essential for products with tight tolerances, such as prosthetics and medical machinery.

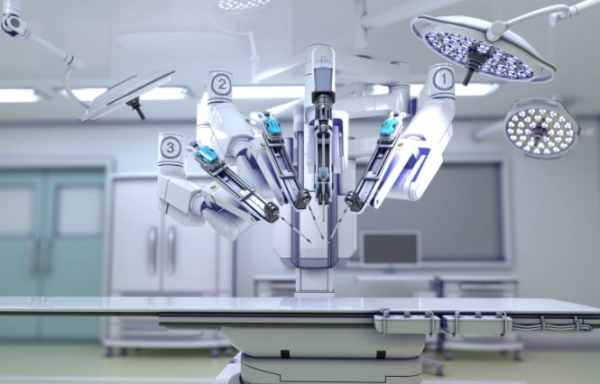

CNC machining can produce high-quality surgical instruments and components for medical machines like pacemakers and surgically implanted devices. Bone screws are a perfect application for Swiss CNC machines.

When it comes to manufacturing screws that are used in medical implants, precision is of utmost importance. These screws can be as small as one millimeter in one direction, have incredibly tight tolerances, and require flawless finishes to avoid patient discomfort and even part failure. To eliminate any contamination concerns, the screws cannot be cut with fluids. This leaves CNC machining as the only viable manufacturing option. Swiss machining is the most effective way to cut a part with a large length-to-width ratio to meet the strict requirements for medical screws.

When designing any medical part, it is crucial to consider either sterilization or disposal, and ensure that the materials used have specific tension and malleability requirements. The materials used in the medical industry reflect this requirement. Approximately four out of five medical devices are made from stainless steel due to its oxidation resistance and ease of machining. Titanium has an elasticity feature. It’s a popular material because it corresponds to bone more closely than stainless steel. Continuous research is being conducted to discover new materials that can be utilized in the medical industry, including ceramics, polymers, and composites.

Medical machining is a complex process that requires cutting tough materials while maintaining safe heat levels and meeting tight tolerances. Enze offers CAD/CAM software solutions to support medical manufacturing shops, including:

– A quick and efficient tool for removing burrs from crucial medical components.

– High-precision toolpaths are available for manufacturing small parts with accuracy.

– Easy to create, import, or modify almost any CAD model.

– Various CAM tools are available to solve complex machining problems.

– Conducted simulation to verify materials’ removal and detect any interferences.

– The 5-axis cutting, trimming, and drilling process is designed to be efficient and precise.

Enze always provides customers with the most cost-effective personalized production solutions.

Making a dedicated mold tool for plastic injection molding can add 3-4 weeks to production lead time. For small production runs, CNC machining offers quick turnaround and minimal investment without needing specialized tools that may increase production time. It benefits the medical industry, where parts must be produced quickly and in small quantities. CNC machining provides excellent quality and accuracy, even without tooling.

Green and durable materials to meet the special needs of medical devices

Design and produce any complex CNC medical parts according to customer drawings and samples

Our skilled team ensures high precision for every medical component processed by CNC.

CNC machining can quickly produce quality medical parts. In emergencies, predicting what parts may be needed is difficult. COVID-19 highlighted the need for personal protective equipment. CNC machining can provide parts rapidly.