Our Location

CNC machining technology is crucial in developing the green energy movement. As more industries and sectors adopt an environmentally conscious approach to business techniques and manufacturing, CNC machining is becoming the preferred technique for producing green energy parts.

The common misconception is that solar panels are the most critical component in solar energy production. However, all assembly components, including the solar panels, frames, infrastructure, and rails, significantly generate power. It’s also important to note that solar panels are used outdoors, so choosing materials that can resist deterioration is crucial.

Despite various challenges, CNC machining is essential for producing complex solar-related components. CNC technology is versatile and can handle a range of materials when making parts effectively. Some CNC drilling and milling machines are specially designed for fabricating solar panel components.

Components such as the carrier rails, frame, and back rails require some tolerances. CNC technology utilizes advanced machining capabilities, including versatile robotic arms and plasma cutters, to produce durable solar components with the desired accuracy. The solar power industry employs turning centers and wired cutters in machining frames and housing within massive production lines.

CNC machining is also compatible with other machining technologies. The hybrid manufacturing approach combines CNC machining with 3D printing to manufacture large solar panels and components while utilizing both techniques to the fullest extent. As a result, most manufacturers can efficiently handle complex parts that may be difficult to machine with CNC machines only.

Wind power production requires sturdy and durable components capable of withstanding enormous stress or load while ensuring uninterrupted operations. Engineers in the wind energy industry develop precise blades to control wind pressure with minimal wear and tear. Therefore, engineers must create precise components during the material selection, design, and production stages.

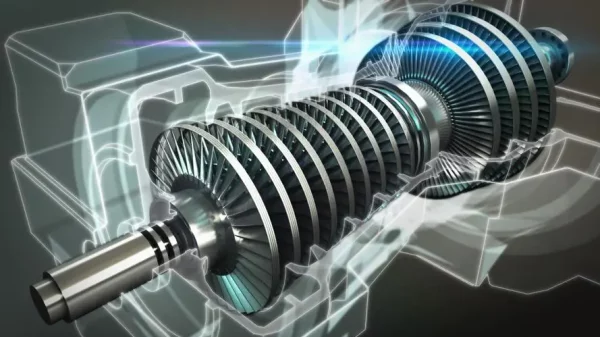

Metal alloys and carbon fiber machining are crucial in manufacturing turbine blades and giant bearings that regulate the angle. CNC technology helps to manufacture the giant bearing within the wind turbine’s adjustment system with the highest accuracy standard in smaller parts machining. This bearing helps to sustain the giant blades’ weight, ensuring unfailing performance.

The wind energy industry’s massive components require precision machining because their mobility significantly impacts their performance. Manufacturers commonly use multi-purpose CNC lathe machines to produce rotors, gears, and gearbox housings. However, due to its size, the average wind turbine requires a giant and heavy-duty machine. The CNC machine must possess precisely 90% of gear wheel fabrication involving metal cutting. Additionally, CNC drills are ideal for processing holes in tube shell heat exchangers for different energy systems.

CNC machines offer ideal economies of scale and are efficient tools for creating wind turbines and windmills from glass fiber or reinforced carbon-fiber plastic materials. However, aluminum, lightweight woods, and fiberglass with hollow cores are typical materials for making rotor blades. Most rotor blades require higher accuracy as they have similar blade profiles to airplanes. Additionally, other wind power generating components, such as gearing mechanisms and rotors, require durability to withstand the heavy load of high wind speed in storms.

Hydropower is a traditional and sustainable source of energy. It involves massive infrastructure and machinery to generate power. However, precision is crucial to ensure the successful operation of hydropower stations, which demands high machinery durability. CNC machining significantly impacts the development of hydro generators, hydro turbine housings, and other related parts. With CNC technology, various hydropower components can be produced efficiently and accurately, from small bushings to large shafts.

Additionally, the CNC milling technique and other technologies facilitate the creation of dam gates and hydropower stations, besides hydropower turbines. The ability of CNC machines to work in various applications or situations is vital for the hydropower industry. Furthermore, the on-site operation of CNC machines significantly reduces the risks and costs of transporting large components to the dam site.

CNC turning and milling technologies are not limited to manufacturing green energy parts. They also play a significant role in producing generators and turbines. CNC machines provide the precision, strength, and dependability needed for turbine parts, including simple shafts, large impellers, and other power generation units.

The use of CNC machining in developing renewable energy systems is significant due to its efficiency and quality. This section will discuss the advantages that make CNC machining the preferred choice for the green energy industry.

CNC milling and turning machines offer fast and efficient manufacturing capabilities and can operate continuously with minimal human intervention. Many machine shops rely on CNC technology for effective and consistent management. These machines produce high-quality machined components in less time while maintaining quality even during complex machining processes.

One of the many benefits of CNC machining is its ultra-precision manufacturing methods. These methods consistently deliver high-precision parts that meet industry standards. CNC machining is an exact and reliable manufacturing process that eliminates the risk of human error during machining. It relies not on the operator’s expertise to produce high-precision components but on the correct programming code input. This means that CNC machining provides consistent and accurate results, even for part tolerances as small as microns. As a result, it can repeatedly create parts with exact specifications with minimal chances of error.

CNC machining is versatile. It is popular among manufacturers. It uses CNC milling and turning techniques to work with materials like metals, plastics, and wood. This process offers designers an extensive list of materials, resulting in a better-performing final product. CNC machines’ compatibility with comprehensive materials in the energy sector helps product engineers make more durable parts. Designers and manufacturers can choose materials strong enough to withstand water damage, pressure, and thermal stress while ensuring consistent performance.

CNC machining offers unique manufacturing processes to the energy sector that do not apply stress on the CNC machined parts. Although part machining generally requires accuracy and expertise to ensure all aspects meet necessary quality standards, CNC machining eliminates all problems. With abundant CNC techniques, you can draft designs and create components faster, more effectively, and at cheaper rates.

Manufacturers are emphasizing eco-friendly production in CNC machining. Lean manufacturing strategies are employed to reduce waste production and energy consumption during the manufacturing process. CNC machining also promotes the production of recyclable and reusable materials such as metals and plastics.

The sustainable green energy industry has a promising future. It’s not just governments adopting renewable energy practices; other companies are encouraged to follow suit as it is an attractive choice and a driving force for modern industries.

Additionally, more countries and renewable energy investors are investing in and advocating for legislation supporting clean energy, while industries are also beginning to take the same route. Therefore, applying an environmentally friendly approach to components machining is crucial, regardless of the company’s industry.

As a result, CNC machining technology is rapidly becoming the foundation for the green energy movement. Because various industries and sectors are adopting a more environmentally conscious approach to business techniques and manufacturing, more significantly, CNC machining will eventually become the most preferred technique for producing green energy parts because of its ability to develop precise, high-quality components.

New energy refers to energy obtained from sources that can be replenished naturally, such as

In 2021, New energy power generation surpassed fossil fuel generation for four out of the last five quarters, according to GOV.UK. Wind power constituted the largest percentage of renewable energy in the first quarter of 2020. These statistics highlight a significant increase in the use of new energy sources. Wind energy, in particular, relies on wind turbines composed of numerous CNC parts. Given the nature of how a wind turbine operates, precision is crucial.

CNC machining can be used for producing solar panel components. These components include frames, back rails, and carrier rails, which can be manufactured using CNC Milling and Extrusion machines. However, larger-scale solar panel production may require additional machine techniques such as cutting or milling. It is important to remember that non-CNC processes are also necessary, as multiple operating parts need to be considered in the design of CNC machined components.

CNC machining is a popular choice for producing parts in the renewable energy sector due to several reasons:

The renewable energy industry heavily relies on CNC machining for the speed and accuracy at which parts can be produced. This speed and accuracy result in fast production times and reduced overall costs since the parts are mass-produced and rely mainly on automation.