Our Location

Part Name: Brass Forging Parts

Brand Name: Enze

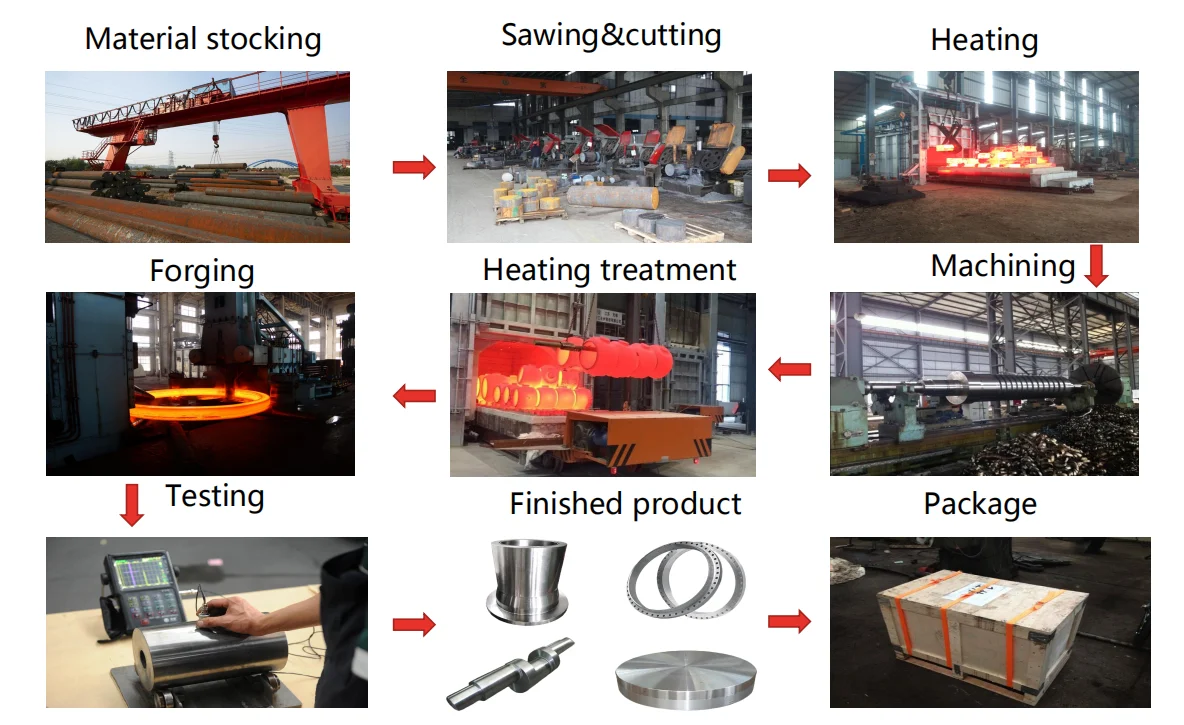

Process: Hot forging

Material: Brass

Surface Treatment: Sandblasting

Application: Automobile, agricultural machinery, furniture, construction, home appliances, electronics.

Quality control: Certificates for all requirements Test reports for every delivery

Drawing format: IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.

Deep Processing: CNC Machining / Cutting / Punching / Inspection / Tapping / Drilling / Milling

We are manufacturer of brass forged components. Our range of forging presses includes mechanical crank and friction screw presses, with a capacity ranging from 10 to 400 tons.

We offer various brass forging services, including cold forging and hot forging. We also provide CNC machining, metal fabrication, and other services. Our forged parts cover many applications, including nuts, hose nipples, tees, elbows, flare, and other components. With our experience and advanced facilities, we can produce high-quality brass forged parts to meet your requirements.

Our factory is equipped with shot blasters, Automats, lathes, drilling and screwing compound machines, and polishing machines. We also offer post-forging deburring, shot blasting, polishing, and machining as per customer specifications.

The forging process can produce stronger parts than any other metalworking process. Due to this strength, forgings are used when reliability and human safety are critical. Hot and cold forging brass can create articles with irregular shapes that cannot be machined or milled on traditional lathes.

Here’s a list of our forged products range:

– Brass Forged Valve

– Brass Forged Tee Joint

– Brass Forged Hand Shut Off Valve

– Brass Ball Valve

– Brass Forged Female Cross Way

– Brass Forged Elbow Fittings

– Brass Forged Automotive parts

– Precision Forged parts

– Forged Immersion Components

– Brass Forged Fittings

– Brass Forged Flange

– Brass Forged Flange

– Brass Forged Adapter

– Brass Forged Reducer

– Brass Forged Head

– Brass Heating Elements Parts

– Brass Screw plug

– Brass Forged Head

– Brass Forged Water and Valve Fittings

Raw material options include Forging Brass per BS 218, High-Grade Free Cutting Brass, IS 319 Brass Free Cutting, and Free Cutting Brass per BS 249 type (i), with the option for special brass material compositions per customer requirements.

Various surface finishes, including Zinc, tin, nickel, chrome, silver, gold, and more

Metric, MM, PG, UNF, UNEF, BSW, BSP, BA, NPT, NPTF, UNC, BSB, BSF.

Range From 0.05 kg to 15.00 kg.

As one of China’s famous brass forging companies, Enze offers cost-effective solutions for your brass-forged products. Our team provides fast quotes and works within your budget. Contact us at admin@enze-mfg.com for more information.