Our Location

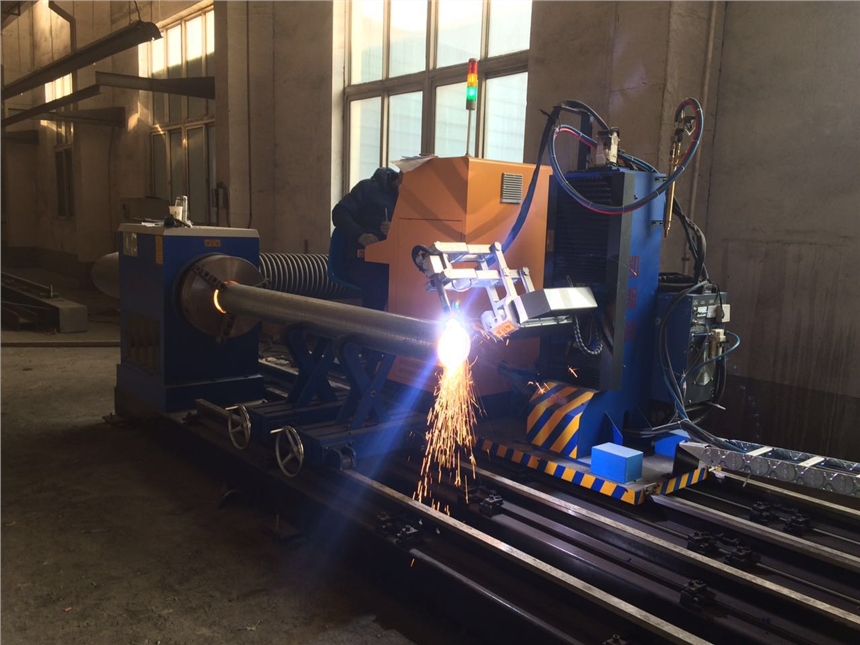

1) Welder Brand: Lincoln Electric

2) Weldings: plasma welding

3) Tools: plasma cutter

3) Materials: Carbon steel

Plasma welding, also named plasma arc welding (short for PAW), is a versatile, high-performance welding process that is applied in many industrial domains.

It can produce top-quality welds, making it popular among industrial welding professionals. In this process, a high-temperature, ionized gas called plasma creates and maintains an electric arc between a welding electrode and a workpiece. The intense heat generated by the plasma arc melts the base metal and filler material (if used), resulting in a strong and precise weld. An inert gas like argon is used in this process to create a protective environment around the arc and weld zone, which prevents contamination of the weld by oxygen from the air and ensures a high-quality weld.

A complete understanding of the plasma welding process is essential for efficient plasma arc welding.

Before starting the plasma welding process, it is crucial to prepare all the parts by cleaning surfaces to remove contaminants such as rust, grease, or paint residues. Chamfering or deburring may also be necessary to ensure successful fusion and metal adhesion, resulting in a high-quality weld.

The electrode is mounted to set up the plasma welding equipment, the power supply and shielding gas cables are connected, and all safety parameters are checked. A typical plasma welding equipment includes a power source, a plasma welding torch, and a cooling system.

Before starting welding, one needs to adjust settings and parameters according to the material, the thickness of the parts, and any welding specifications. Variables specific to the plasma welding project, such as electric current intensity, wire feed speed, shielding gas pressure, and the distance between the electrode and workpiece, must be verified to ensure precise settings and parameters for optimum metal fusion and penetration.

The operator directs the plasma welding torch along the welding area, which generates an electric arc and intense plasma. The thermal energy of the plasma melts the base metals and filler material, forming a solid, homogeneous weld. The operator must use proper welding techniques to achieve optimum results, control feed speed, and maintain a constant distance between the torch and the workpiece.

Plasma welding is a versatile welding method used in various industries for its precision and reliability. It is widely used in the construction industry to join steel structures, beams, frames, and other components. In the automotive industry, it creates precise, high-quality welds on car parts, offering high weld strength and durability. In the aerospace industry, it is used to join aircraft structures, fuel tanks, piping, and other components, producing lightweight, strong welds that meet stringent performance and safety requirements.

By concentrating heat generated by the plasma arc, it produces high-quality welds that are free from defects. It creates a total fusion of materials, ensuring a solid, homogeneous connection. Plasma welding is ideal for welding small parts or thin materials that require high precision. It helps reduce the material that needs to be removed during finishing, simplifying post-processing operations.

However, it requires specialized equipment such as a plasma arc generator and plasma welding torches, which can be expensive to install and maintain.

Plasma welding generates very high temperatures that can cause welded parts to deform. To minimize distortion, special cooling devices are required during the welding process. Moreover, it may not be suitable for applications requiring high mobility or restricted access, as the equipment size and handling of the plasma arc make it difficult to weld in tight spaces or hard-to-reach positions.

If you need to create high-quality welds, work on precise joints, or be able to weld a variety of materials, plasma welding could be the right solution.

If you need high-quality welds or precise joints on various materials, plasma welding could be the right solution. Enze has extensive experience in plasma welding and other types of welding. We offer a qualified team with the latest welding technologies as industrial welding professionals. Contact us now to get a fast offer.