Our Location

Stainless steel is an alloy made with a combination of chromium, nickel, and other metals that provide excellent resistance to corrosion. Over 100 unique grades of stainless steel are available, with most falling into five broad categories.

Stainless steel comes in different types, each with unique characteristics. These properties determine the strengths and weaknesses of each type for specific applications. This article focuses on ferritic stainless steel, providing essential information on how it is classified and what makes it different from other types of stainless steel.

Table of Contents

ToggleFerritic steel is a stainless steel alloy with more than 12% chromium. It differs from other types of stainless steel in two essential ways: its chemical composition and molecular grain structure. Here are some of the critical things you should know about these variations.

Ferritic stainless steel is classified as a straight chromium, non-hardenable category of stainless alloys with chromium content ranging from 10.5% to 30% and a carbon level under 20%. These steels can’t be hardened by heat treatment and are only slightly hardenable by cold rolling.

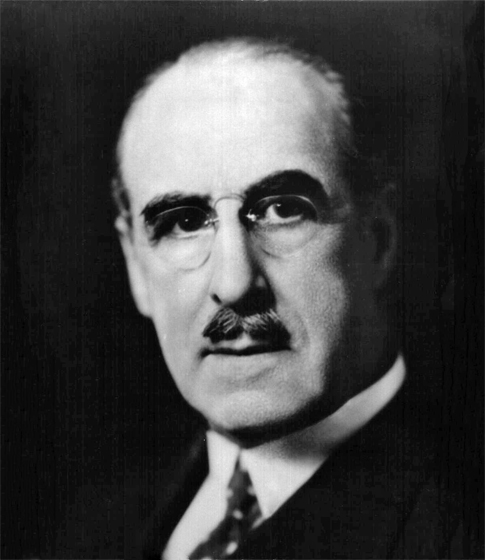

A Canadian engineer, Frederick Mark Becket (1875-1942), industrialized ferritic stainless steel around 1912. He used silicon instead of carbon as a reducing agent in metal production, which made low-carbon ferroalloys and certain steels practical. He discovered a ferrous alloy with 25-27% chromium, the first high-chromium alloy known as heat-resisting stainless steel.

Ferritic stainless steels were discovered early, but their growth was only possible in the 1980s:

Frederick Mark Becket (1875-1942)

Ferritic stainless steel is produced by melting steel and then adding the necessary elements to create the desired alloy. This molten mixture is cast into various shapes, such as slabs, billets, or blooms, using pour-casting or continuous-casting methods. The cast material is then hot or cold rolled or forged into the required shapes, such as plates or sheets. To refine the microstructure and relieve stresses, the material is annealed by heating it to a temperature that dissolves crystal boundaries and then gradually cooling it. Other alloying elements may be added as needed throughout the manufacturing process to achieve the desired composition. The melting and casting processes are typically carried out in an electric arc or induction furnace in an environment that maintains purity, such as an inert atmosphere or a vacuum. Finally, the material is subjected to various final manufacturing processes.

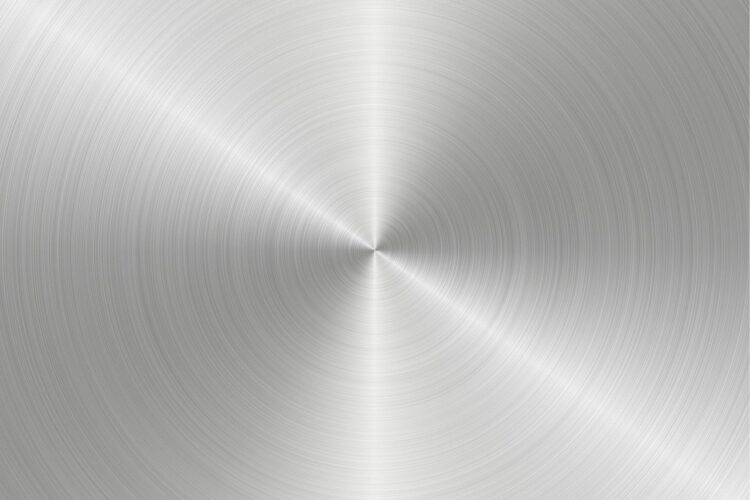

Ferritic alloys are a type of stainless steel with a shiny silver finish. When polished flat, they can reflect light like a mirror without distorting its color. In everyday use, ferritic components have a slightly textured or matte surface or a highly polished and reflective finish.

Please find below the chemical compositions of different elements in Ferritic stainless steel arranged in a tabular format for your reference.

| Element | Percentage |

| Iron (Fe) | 65-72% |

| Chromium (Cr) | 16 – 24% |

| Carbon (C) | < 0.08% |

| Nickel (Ni) | < 2.0% |

| Manganese (Mn) | < 1.0% |

| Silicon (Si) | < 1.0% |

| Phosphorus (P) | < 0.04% |

| Sulfur (S) | < 0.03% |

| Nitrogen (N) | < 0.1% |

| Molybdenum (Mo) | < 2.0% |

| Titanium (Ti) | < 0.1% |

| Copper (Cu) | < 0.5% |

| Selenium (Se) | < 0.5% |

| Aluminum (Al) | < 0.5% |

| Vanadium (V) | < 0.2% |

Different alloys are utilized in ferritic steel grades depending on the specific application. Ferrites can be classified into five major groups.

The first group of stainless steels is characterized by having the lowest chromium content and the lowest price. Initially intended for automotive exhaust systems, type 409 is now widely used for catalytic converter casings. Type 410 L is used primarily for LCD monitor frames, containers, and buses.

Type 430 is a popular type of ferritic steel containing chromium in the 16% to 18% range. This makes it more resistant to corrosion compared to group 1 ferrites. Type 430 is commonly used to manufacture washing machine drums, kitchen sinks, and other kitchenware. Due to its similar characteristics, it can also be used as a substitute for type 304 in many applications, such as indoor panels.

Group 3 ferritic steels have a chromium content between 17.5% and 18.5%. They possess excellent weldability and formability, sometimes even superior to 304 steels. These properties make them a wonderful substitute for a variety of applications currently using 304 steels. Some of these applications include exhaust systems, sinks, and exchange tubes.

Group 4 ferritic steel types contain molybdenum, increasing their corrosion resistance. These steels are commonly used in hot water tanks and outdoor applications exposed to corrosive environments.

The steels in the last group are typically used in environments that are highly prone to corrosion. These types of ferritic steel contain a high proportion of chromium and molybdenum, which gives them outstanding corrosion resistance properties. In fact, their performance can be compared to that of titanium metal, which makes them the perfect choice of steel for applications such as heat exchangers, water heaters, and boilers.

| ASTM A240 | EN 10088-2 | ||||||

| — | UTS (MPa, min) | 0.2% yield stress (MPa, min) | Elongation (%, min) | — | UTS (MPa) | 0.2% yield stress (MPa, min) | Elongation (%, min) |

| 9 | 390 | 170 | 20 | 1.4512 | 380 – 560 | 220 | 25 |

| 410 | 415 | 205 | 20 | 1.4003 | 450 – 650 | 320 | 20 |

| 430 | 450 | 205 | 22 | 1.4016 | 450 – 600 | 280 | 18 |

| 439 | 415 | 205 | 22 | 1.451 | 420 – 600 | 240 | 23 |

| 441 | 415 | 205 | 22 | 1.4509 | 430 – 630 | 250 | 18 |

| 434 | 450 | 240 | 22 | 1.4113 | 450 – 630 | 280 | 18 |

| 436 | 450 | 240 | 22 | 1.4526 | 480 – 560 | 300 | 25 |

| 444 | 415 | 275 | 20 | 1.4521 | 420 – 640 | 320 | 20 |

| AISI / ASTM | Young’s Modulus(GPa) | Density(g/cm3) | Electrical Resistance(μΩ·m) |

| 409 / 410 | 220 | 7.7 | 0.58 |

| 430 | 220 | 7.7 | 0.6 |

| 430Ti / 439 / 441 | 220 | 7.7 | 0.6 |

| 434 / 436 / 444 | 220 | 7.7 | 0.6 |

| 447 | 220 | 7.7 | 0.62 |

| AISI / ASTM | Specific Heat 0…100 °C(J/(kg·K)) | Thermal Conductivity at 20 °C (W/(m·K)) | Thermal Expansion 0…600 °C (10−6/K) |

| 409 / 410 | 460 | 25 | 12 |

| 430 | 460 | 25 | 11.5 |

| 430Ti / 439 / 441 | 460 | 25 | 11.5 |

| 434 / 436 / 444 | 460 | 23 | 11.5 |

| 447 | 460 | 17 | 11 |

Although ferritic steels cannot be hardened or strengthened through heat treatment, they can be softened by undergoing an annealing process that involves heating and cooling the metal. Ferritic grades have advantageous mechanical properties but are less strong or corrosion-resistant than austenitic steels. Ferritic steels are generally easy to weld, but some grades have limitations that restrict their use to thinner gauges.

Standard ferritic stainless steels are less expensive than austenitic grades because they lack nickel and have lower amounts of chromium. SS430 denotes the most commonly used ferritic stainless steel. Due to its low chromium content, SS409 is less resistant to corrosion. On the other hand, SS439 is more corrosion-resistant and stable at high temperatures. Ferritic stainless steels offer a range of beneficial properties depending on the alloy.

Stress corrosion cracking (SCC) is a common type of steel damage that occurs due to both tensile stress and a corrosive environment. Austenitic stainless steels are especially prone to SCC when exposed to chlorides. On the other hand, ferritic steels have microstructures that make them highly resistant to SCC. As a result, they are an excellent choice for use in environments that contain chlorides.

Carbon is responsible for providing steel with its hardness, but at the same time, it makes it more brittle and less ductile. Ferritic steel, which contains low levels of carbon, as little as 0.03 percent, is known for its excellent ductility, which allows it to be shaped extensively without any risk of weakening.

The low carbon content in ferritic steel also makes it highly formable, which means it can be transformed into various shapes without cracking or necking.

However, the benefits of ferritic steel’s low carbon content come with inevitable trade-offs. For instance, ferritic steel cannot be hardened through heat treatment, and it may exhibit specific problems during welding, such as unwanted cracks along the heat-affected zone.

Ferritic steels possess a crucial advantage in that they have a naturally low coefficient of thermal expansion. This means that as they are heated, they will expand less and retain their fixed dimension more readily. This property is especially useful for metals used in high-temperature applications.

Ferritic steels demonstrate excellent thermal conductivity, allowing heat to move efficiently through them. As a result, they are a popular choice for furnace and boiler heat exchangers and other applications involving heat transfer.

Ferritic stainless steel is known for its exceptional oxidation resistance, especially at high temperatures. This is because a layer of chromium-oxide forms on the surface of the steel, which acts as a protective film. Manufacturers can enhance this resistance further by adding aluminum or silicon during the production of ferritic steel.

Ferritic stainless steel contains a certain amount of iron, which makes it magnetic. This type of steel is one of the most magnetic materials due to its high iron content, making it more susceptible to magnetism.

The degree of magnetism in stainless steel is directly proportional to the amount of ferrite, which is a form of iron oxide. Therefore, the more ferrite present, the stronger the magnetic properties of the steel.

However, although ferritic steel is magnetic, it may not always be suitable for applications requiring strong magnetic fields, such as MRI scanners. In such cases, austenitic steel is used instead, as it is non-magnetic.

Ferritic stainless steel can be welded, but it is more challenging than welding other types of stainless steel. This is because ferritic steel has a higher carbon content and lower melting point, making welding more difficult. Furthermore, ferritic steel is more prone to cracking during welding due to its low ductility.

To minimize the risk of cracking, it is crucial to use the correct welding technique, select a filler material with low carbon content, and preheat the workpiece. By following the appropriate welding techniques, using the proper filler material, and preheating the workpiece, you can ensure a successful weld when working with this specific type of steel.

If you select ferritic stainless steel, it will provide numerous benefits for your fabrication projects and applications.

Although ferritic steel has several benefits, it has a few drawbacks.

Ferritic and austenitic stainless steel are two major types of stainless steel. Ferritic stainless steel is composed of a ferrite matrix with a body-centered-cubic (BCC) crystal structure. It is magnetic and has excellent ductility and formability properties.

On the other hand, austenitic stainless steel comprises austenite with a face-centered-cubic (FCC) crystal structure. It has non-magnetic properties and higher strength.

How do they differ from each other?

Both ferritic and austenitic stainless steels have different crystal structures and magnetic properties. Their main differences lie in the applications for which they are best suited.

Ferritic stainless steel is known for its strength and ductility, making it ideal for use in automotive parts, kitchen utensils, and pipelines. When it comes to chemical processing equipment, austenitic stainless steel is a great option thanks to its exceptional strength and corrosion resistance, such as in kitchen appliances and surgical instruments.

Despite their differences, both types of stainless steel have unique applications and benefits.

Ferritic stainless steel has a body-centered cubic (BCC) crystal structure and provides excellent corrosion resistance in moderate environments. On the other hand, martensitic alloys have a body-centered tetragonal (BCT) crystalline matrix. Both ferritic and martensitic stainless steels exhibit varying degrees of high magnetic permeability, depending on their alloy composition and work hardening and manufacturing processes.

Martensitic stainless steels can usually be heat/quench hardened and tempered, whereas ferritic alloys are not heat-treatable. Ferritic stainless steels also tend to be more corrosion-resistant than martensitic alloys, although this can vary depending on the specific alloys being compared.

Finally, martensitic alloys are stronger and more abrasion-resistant than ferritics, but this, too, depends on the particular alloys being compared and the manufacturing processes used.

To prevent rust on steel, perform regular maintenance. Here are step-by-step instructions to help you maintain the material.

You now understand the significance of ferritic stainless steel, which is generally used in various industries such as food processing, automotive, and chemical. This knowledge will help you decide when and where to utilize it. Additionally, you have learned how to maintain this material to ensure it lasts longer appropriately.

Nitronic 50 is a premium austenitic stainless steel with better corrosion resistance than the 300 or 400 stainless steel series. Due to its superior strength, excellent corrosion resistance, and low magnetic permeability, it is highly preferred for high-risk applications such as medical implants.

430F is easier to machine than 430 stainless steel due to its higher sulfur and molybdenum content, but it’s more difficult to form.