Our Location

In the realm of advanced manufacturing and metallurgy, the Electron Beam Melting (EBM) machining process stands out as a key technology, offering distinct advantages in producing complex parts with high precision. EBM is a layer-by-layer additive manufacturing technology that is revolutionizing the way industries produce metal components. This article post will delve into the fundamentals of the EBM machining process, examining its principles, benefits, applications, and future prospects.

Table of Contents

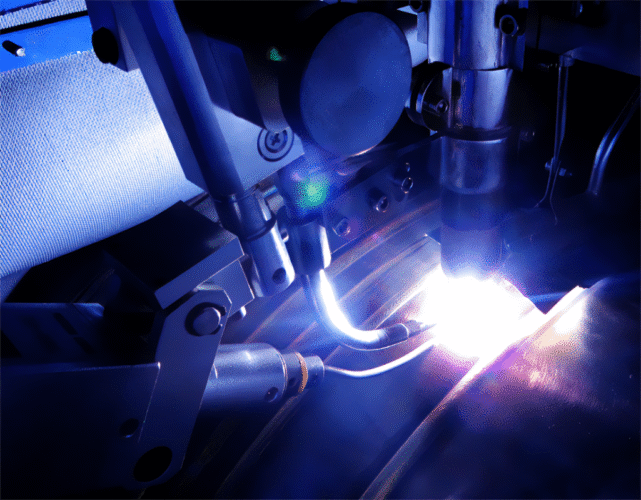

ToggleElectron Beam Machining (EBM) is a non-contact machining process, meaning that the tool—the electron beam—does not physically touch the material being worked on. Instead, it utilizes a high-energy beam of electrons focused on a small area of the material. The energy generated by the electrons produces heat, which either melts or vaporizes the material to create the desired cut or shape.

You may be curious about the origins and development of Electron Beam Melting (EBM) technology. The history of EBM 3D printing began with German physicist Dr. Karl-Heinz Steigerwald, who invented electron beam technology.

He successfully developed the first operational electron beam machine in 1952. By the early 1990s, the German company H.C. Starck GmbH had started using EBM technology to manufacture various industrial components.

Arcam, a German company, collaborated with Chalmers University of Technology to jointly patent EBM technology in 1993. Four years later, EBM 3D printing was commercialized with the formation of a new company, Arcam AB. In 2016, General Electric (GE) successfully acquired Arcam AB and has since become the provider of EBM 3D printing technology.

EBM systems consist of several key components, including:

High voltage power supply – The system accelerates electrons to an energy level of up to 60 kV.

Electron gun – It produces a narrow beam of high-energy electrons.

Beam control – Electromagnets are used to guide and deflect the electron beam.

Build platform – The pressure decreases gradually as more layers are added.

Powder dispensing – It involves depositing and spreading layers of metallic powder.

Powder cassettes/hoppers – Store and deliver powdered substances.

Vacuum chamber – This system provides a high-vacuum environment.

Heating coils – The powder bed is preheated to a temperature of up to 1000°C.

Control console – Computer and software are necessary to operate the system.

The most common materials used in EBM are:

EBM usually takes place within a machine that operates under vacuum conditions and at extremely high temperatures. The process can be divided into the following steps:

The EBM machining process’s versatility makes it essential in various industries. Here are some significant applications:

The automotive industry employs EBM to produce high-performance parts, such as engine components and specialized tools. The lightweight characteristics of EBM-manufactured parts enhance the overall performance of vehicles.

EBM technology is primarily utilized in the aerospace sector to manufacture lightweight yet durable parts, such as turbine blades and structural components. Its capability to create complex shapes significantly improves fuel efficiency.

Precision tooling is a field where EBM excels, enabling the production of intricate molds and dies that enhance product quality and manufacturing efficiency.

In the medical area, custom implants and prosthetic devices benefit from the precision and customization provided by EBM. The tailored characteristics of these parts are crucial for applications that require a precise fit for patient-specific needs.

Although the EBM machining process is revolutionary, it’s essential to compare it with other additive manufacturing methods, for example, Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM).

SLM and DMLS support a wider variety of materials, whereas EBM is mainly used for reactive and high-performance alloys, making it ideal for specialized applications.

The EBM machining process takes place in a vacuum, which reduces oxidation and contamination, leading to the production of high-quality parts. In contrast, laser-based methods typically operate in an argon or inert gas environment, which may not meet the same purity standards as EBM.

The primary difference among EBM, SLM, and DMLS lies in the energy sources used for processing. EBM utilizes an electron beam, whereas SLM and DMLS rely on lasers. This distinction affects the melting rates and the thermal impact on the material. Generally, EBM demonstrates faster processing speeds due to the higher energy density of the electron beam.

Emerging Materials for EBM

Future developments will broaden EBM’s material compatibility beyond conventional metals such as titanium and nickel alloys. Research is focused on new alloys and composites that possess superior mechanical properties and biocompatibility, which will open up new opportunities in medical, aerospace, and other specialized industries.

Innovations in EBM Technology

Innovations are continually aimed at enhancing precision, quality, and speed. Advancements in electron beam systems promise faster scans and improved control over build parameters, thereby minimizing residual stresses and optimizing part production.

Potential Industry Impact

EBM has the potential to transform various industries by facilitating the production of lightweight, intricate parts with high strength. In the aerospace sector, this advancement can lead to improved fuel efficiency and overall performance.

In the medical field, EBM enables the creation of personalized implants tailored to individual patients. Meanwhile, the automotive industry can leverage rapid prototyping and the production of custom parts, which enhances efficiency and reduces costs.

Predictions for EBM in Manufacturing

The adoption of EBM is expected to increase as materials and processes continue to advance. EBM may transition from being primarily used for prototyping to becoming a mainstream production method. This shift will enable on-demand manufacturing, reduce lead times, and minimize material waste.

EBM is set to play a vital role in additive manufacturing by enhancing production efficiency and addressing various manufacturing requirements.

Electron Beam Melting (EBM) is revolutionizing additive manufacturing by enabling the efficient creation of precise, high-strength parts. Despite facing initial challenges, continuous advances in EBM technology and materials are broadening their applications across various sectors, including automotive, medical, aerospace, and research.

The ability of EBM to streamline production, reduce waste, and promote innovation positions it as a crucial player in the future of manufacturing.