Our Location

CNC routing is an automated process that utilizes a specialized tool to cut materials, such as plastics, wood, polyurethane foam, and soft metals, into different shapes.

This technology utilizes CNC machines that follow computer-generated instructions to move high-speed tools to various coordinates and preferred designs. Understanding this machining approach is essential for maximizing benefits.

This text covers the fundamentals of CNC routing, explaining how it operates and the essential components of a CNC router. You will also discover the different types of CNC routers, along with the benefits and limitations of the process. Be sure to read to the end for complete insights!

Table of Contents

ToggleThe first question that may come to mind is, “What is CNC routing?” CNC routing is a popular machining method used in modern manufacturing. Similar to other forms of CNC machining, routing involves shaping materials into the desired form or geometry. The key difference lies in the tooling and capabilities used in the process.

The routing machine utilizes a specialized tool known as a router, which has a rotating bit. This router moves across the workpiece according to instructions provided in G-code and follows predetermined tool paths to perform machining operations. Additionally, the setup includes a large CNC bed and applies low tool pressure. Consequently, routing operations are ideal for working with thin and large sheets of material.

Computer-controlled routing is a crucial process utilized across various industries. The CNC (Computer Numerical Control) router operates through a series of precise steps designed to guarantee that the final product fulfills the customer’s specifications. Below is a breakdown of how the CNC router performs its operation:

The functionality of a CNC router depends on various essential parts working together seamlessly. Some of its main components include the following:

Body or Frame

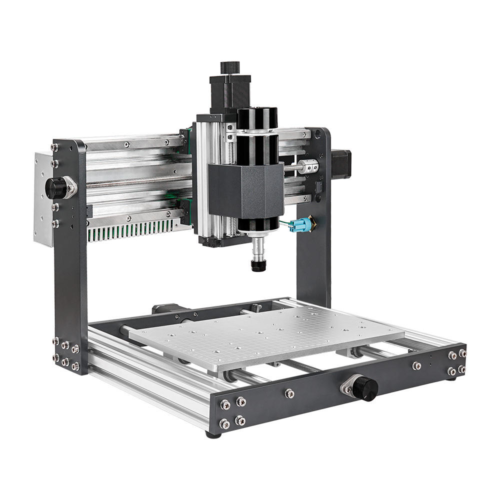

At the centre of a CNC router is its frame, made from strong materials such as aluminum alloy or steel. This construction provides the necessary stability and support for the workpiece, ensuring precise cutting by minimizing vibrations.

Controller

The controller is the primary system for the CNC router, transmitting G-code to the machine and controlling all mechanical components. It manages cutting speeds, tool positions, and depths to achieve precise machining results.

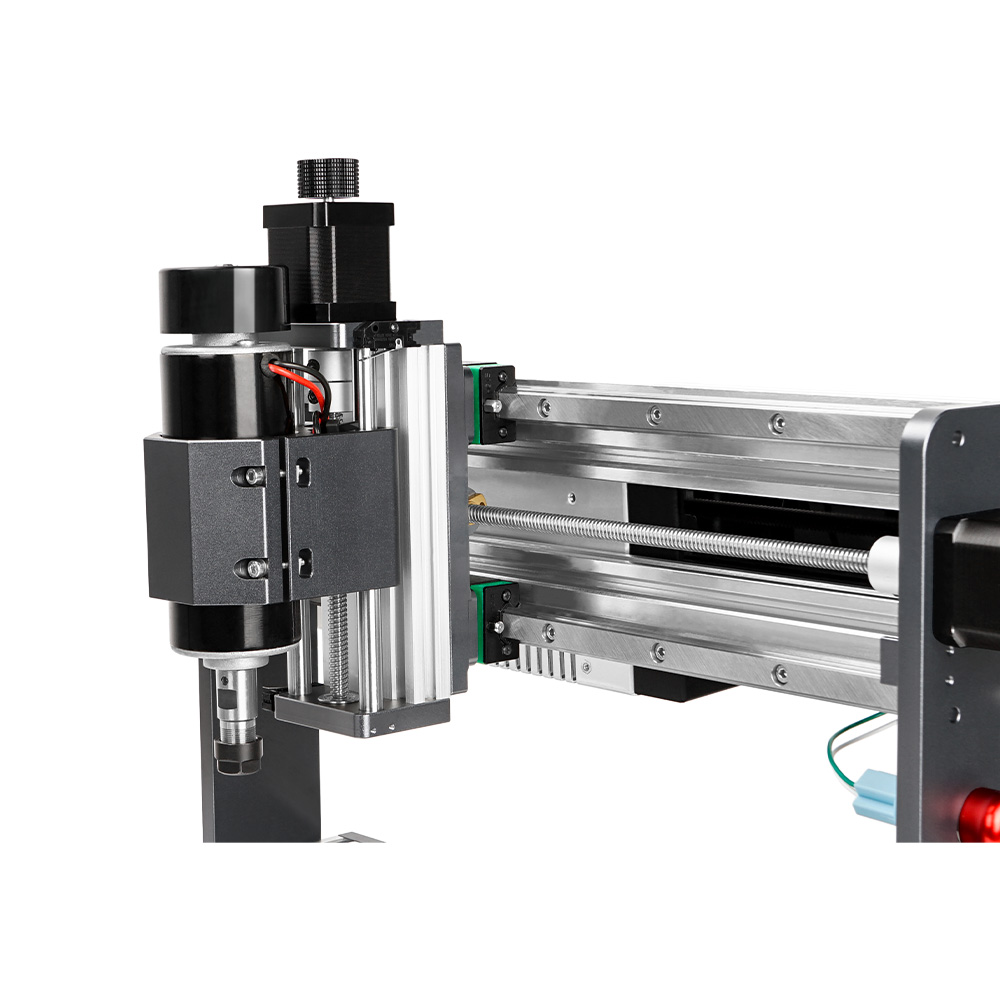

Drives and Motors

CNC routers utilize servo or stepper motors for movement. Stepper motors offer incremental motion without feedback, while servo motors provide enhanced accuracy through position feedback systems.

Linear Guides and Rails

Smooth tool movement on a machine’s axes is facilitated by linear rails and guides. These components utilize machined surfaces and bearings to ensure minimal friction and precise tool placement.

Spindle

Spindles are components that rotate and protect cutting tools. Motors power them and operate at varying speeds. The speed and quality of cuts depend directly on the spindle’s quality.

Collet or Tool Holder

Ensuring a firm attachment of cutting tools to the spindle is the role of the tool holder. This component prevents unwanted movement during operations, which is essential for achieving accurate results.

Workholding System or Vacuum Table

A vacuum table maintains material stability during the cutting process. This setup utilizes suction with adjustable zones and an MDF spoilboard to evenly distribute vacuum pressure across the workpiece.

Limit Switches

Limit switches are utilized to prevent the machine from exceeding its operational range. These protective devices serve as origin points and automatically stop movement when the machine reaches its boundaries.

Cooling System

The cooling mechanism prevents overheating of cutting tools and the spindle, ensuring consistent cutting quality and prolonging the lifespan of tools.

User Interface and Software

CNC routers utilize control software to transform designs into machine instructions. GRBL and Fusion 360 are user-friendly interfaces that help operators monitor machine operations and program cutting paths.

There are diverse machines in the world of CNC routing, each specifically engineered to meet the unique needs of your project. This section concerns the different CNC routers available based on their features, capabilities, and applications:

Industrial Router

Industrial routers are designed for heavy-duty manufacturing and come equipped with high-power spindles. These robust machines are capable of handling intensive routing projects and typically require more floor space compared to hobby or desktop routers. Additionally, industrial routers play a crucial role in woodworking, metal fabrication, aerospace, automotive, and marine industries, providing fast and accurate machining of various parts.

ATC (Automatic Tool Changer) CNC Routers

Automatic tool changer routers are complex machines equipped with an automated tool-changing mechanism that enables them to swap tools without requiring the machinist’s intervention. This feature significantly enhances productivity and efficiency, particularly in tasks requiring multiple cutting tool types.

ATC routers are primarily used in production environments where time is crucial and precision is essential. Their remarkable ability to reduce downtime and human error makes them valuable assets for large-scale, intricate projects.

Multi-Axis CNC Routers

For complex machining, there are routers available with different axis capabilities. These machines can have 3, 4, or even 5-axis movement, and in some cases, more than 5 axes. As the number of axes increases, the machines are able to create more complex and precise parts. However, the choice of machine depends on factors such as the complexity of the design, the required tolerances, and the type of material of the workpiece.

Hobby CNC Routers

This CNC routing machine is designed specifically for DIY enthusiasts and hobbyists who engage in CNC routing for personal projects or low-volume production. These machines offer a balance of affordability and performance, providing an entry point into CNC machining without the need for expensive industrial-grade equipment.

Desktop CNC Routers

As the name suggests, compact CNC machines are designed to fit into small workshop spaces or on desks. These CNC routers are ideal for smaller projects and prototyping, providing a cost-effective solution for beginners in the CNC routing field or those with limited space.

Desktop CNC routers offer exceptional precision and versatility, making them fit for machining a wide range of materials, including plastic, wood, and soft metals, regardless of their size. Their ease of maintenance also makes them the most popular CNC routers among hobbyists, designers, and small businesses.

Nested-Based CNC Routers

Nested-based CNC routers are engineered to maximize material usage and efficiency by arranging cutting patterns to minimize waste. This type of CNC router is especially beneficial for industries such as furniture production, cabinetry, and sheet metal fabrication, where optimizing material yield is essential.

The ability to combine software optimization with precise cutting allows nested-based CNC routers to provide both economic and environmental advantages, minimizing waste while upholding high production standards.

The following are the materials for the routing process:

CNC routing technology is utilized across various industries for cutting and shaping in multiple ways.

Signage and Graphics

The sign-making industry utilizes CNC routers for creating 3D signage, engraved plaques, and dimensional letters. Events and businesses hire these machines to produce eye-catching displays from materials such as wood, HDU foam, and acrylic.

Woodworking and Furniture Manufacturing

CNC routers are essential tools in the furniture industry for manufacturing intricate wooden components. They excel at producing cabinet parts, decorative panels, and custom furniture pieces due to their consistent ability to deliver high-quality products. Designs that would take days to complete by hand can now be finished in just a few minutes with modern CNC routers.

Aerospace and Automotive Industry

Although they are not very common, CNC routers are used to create certain aluminum parts for automobiles, such as dashboards and panels. These machines ensure precise specifications for vehicle parts and aircraft panels by producing accurate molds for the manufacturing of these components.

Modeling and Prototyping

CNC routing is highly advantageous for rapid prototyping. Engineers utilize these machines to create precise product models and test pieces before full-scale production. This process is essential for design validation and the effective development of the product.

Plastic and Foam Cutting

Foams and plastics can be effectively shaped for various applications using CNC routers. They are used to create custom packaging, protective cases, and display materials, allowing for the cutting of different material densities without damage.

Enclosures for Electronics and Electricity

CNC routers are utilized in the electronics industry to produce device enclosures and PCB boards. They create precise cutouts for vents, connectors, and mounting points in various materials to ensure a correct fit and function.

The CNC routing process is widely utilized across industries due to its numerous benefits. Here are some expected advantages:

Despite the advantages of the CNC routing process, there are certain limitations:

CNC routing and CNC milling benefit different manufacturing purposes. Routers operate at higher speeds and require less cutting force, making them suitable for materials such as wood, soft metals, and plastics. In contrast, milling machines are more rigid than routers and are capable of machining harder materials with greater cutting forces.

Routers are more suitable for large-scale projects with simpler geometries, while milling machines excel at handling complex and detailed work that requires stricter tolerances. The choice between these methods depends on the project’s specific requirements. CNC routing is a faster and more cost-effective solution for softer materials, whereas milling offers better precision for complex metal components.

CNC routing is a versatile subtractive manufacturing technology known for its high precision and accuracy. Most CNC routers are primarily designed for cutting softer materials. Additionally, gantry-style CNC routers tend to be less rigid than traditional CNC mills when working with harder materials. This guide has covered all the necessary information to help you choose the right CNC router machine for your project.