Our Location

Stainless steel is a widely used material known for its outstanding properties, such as corrosion resistance, heat resistance, high strength, cleanliness, etc. There are five different types of stainless steel, each with a unique chemical composition. Martensitic steel is a popular choice for its strength, durability, and corrosion resistance. These qualities make martensitic steel an ideal choice for various applications. Today, we will explore the properties, composition, advantages, and applications of martensitic steel across multiple industries.

Table of Contents

ToggleMartensitic stainless steel is different from other types due to its composition. It mainly comprises iron, carbon, and other alloys, such as chromium and nickel. The high carbon content of about 1.2% gives it its strength, but it has lower corrosion resistance than other stainless steels due to the lack of significant nickel. This type of steel can be hardened and strengthened through heating and aging, which sets it apart from other stainless steels.

In 1912, while looking for a corrosion-resistant alloy for gun barrels, Harry Brearley of the Brown-Firth research laboratory in Sheffield, England, discovered a martensitic stainless steel alloy. He later industrialized it, and in January 1915, The New York Times published an article announcing the discovery. During that same year, Brearly applied for a U.S. patent, and the alloy was marketed under the brand “Staybrite” by Firth Vickers in England. This alloy was used in the new entrance canopy in Savoy Hotel in London in 1929.

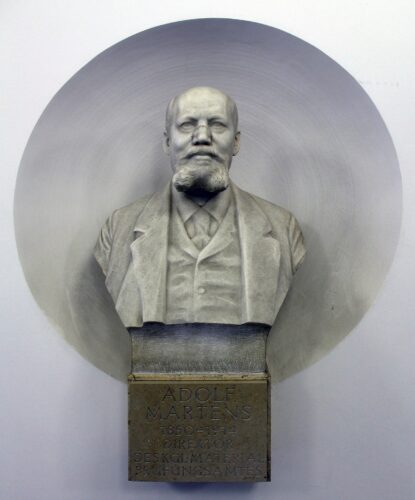

The characteristic body-centered tetragonal martensite microstructure was first observed by German microscopist Adolf Martens around 1890. Elwood Haynes also applied for a U.S. patent on a martensitic stainless steel alloy in 1912, but it was not granted until 1919.

Martensitic stainless steels include Type 410, Type 420, and Type 440A. They respond to heat treatment similar to high-carbon steel alloys. The maximum quenched hardness of martensitic stainless steel is defined by its carbon content.

Hardening is achieved by heating the steel to high temperatures and then rapidly cooling it, often called air-hardening due to the high hardenability of martensitic alloys.

The material is typically heated at low temperatures to relieve stress from its microstructure or at slightly higher temperatures to soften it and achieve intermediate hardness levels. This is because the hardened martensitic material has a brittle structure.

It undergoes annealing if the alloy is heated just below its critical temperature. On the other hand, if it’s heated slightly above the extreme temperature and allowed to cool for a longer period, it undergoes full annealing.

Martensitic stainless steel usually has a silver or gray appearance, but it can also appear orange/brown due to rust or a different color due to paint. If the steel is left unpainted, it may have a reflective or matte finish, depending on the material’s surface texture.

| Element | Percentage |

| Chromium | at least 11% |

| Carbon | 0.15-2% |

| Iron | 11.5%-18% |

| Manganese | 0.01 |

| Silicon | 0.0075 |

| Nickel | 2-3% |

| Phosphorus | less than 0.04% |

| Molybdenum | 2-3% |

| Sulphur | less than 0.03% |

Understanding the various grades of this material can help you select the most suitable one for your application.

410 martensitic stainless steel is a heat-treatable steel that belongs to martensitic grade. It has approximately 11.5-13.5% chromium, which provides it with its corrosion-resistant properties. This grade finds application in situations that demand moderate protection against corrosion and exhibit high mechanical properties:

Aisi 420 ss is a martensitic steel with 12% chromium and 0.15%-0.40% carbon. Its high carbon content provides excellent hardness and resistance to wear. This grade can be used to manufacture medical components such as:

Grade 431 is a martensitic stainless steel alloy with 16-18% chromium. It has a high tensile strength, is heat-treatable, and is resistant to scaling and oxidation. This alloy is generally used in various applications due to its exceptional toughness, such as:

440 Stainless Steel belongs to the high carbon martensitic category, having a chromium content of around 16-18%. It is highly resistant to corrosion and is frequently utilized in:

Low carbon versions of martensitic steel, with carbon content ranging from 0.05% to 0.25%, are stronger, more corrosion-resistant, and have greater potential for fabrication.

High carbon martensitic steel typically contains a higher percentage of carbon, ranging between 0.61% and 1.50%. The increased carbon content enhances the strength of the steel by strengthening its molecular structure. However, its increased brittleness makes it more difficult to weld or shape the steel into other forms.

Martensitic SS is a type of steel with a composition similar to regular stainless steel but with a lower amount of alloy and a higher amount of carbon. These differences give it unique properties such as high hardness, brittleness, moderate corrosion resistance, and high tensile strength. Due to these distinctive characteristics, it is sometimes called semi-stainless steel.

| Type | Mininmum Yield stress | Tensile strength | Minimum Elongation, % | Heat treatment |

| 410 | 50 MPa (65 ksi) | 650–850 MPa (94–123 ksi) | 15 | QT650 |

| 420 | 600 MPa (87 ksi) | 650–850 MPa (94–123 ksi) | 12 | QT800 |

| 431 | 700 MPa (100 ksi) | 900–1,050 MPa (131–152 ksi) | 12 | QT900 |

| 630 | 790 MPa (115 ksi) | 960–1,160 MPa (139–168 ksi) | 12 | P960 |

| In the heat treatment column, QT refers to Quenched and Tempered, P refers to Precipitation hardened | ||||

| Type | ung’s Modulus at 20 °C (68 °F),Gpa | Specific Thermal capacity at 20 °C, J * Kg−1 * K−1 | Mean coefficient of thermal expansion between 20 and 100 °C (68 and 212 °F), 10−6K−1 | Thermal Conductivity at 20 °C, W * m−1K−1 | Electrical resitivity, 10−6Ω * m |

| 410 | 215 GPa (31.2×106 psi) | 460 | 10.5 | 30 | 0.6 |

| 420 | 215 GPa (31.2×106 psi) | 460 | 10.5 | 30 | 0.65 |

| 420MoV | 215 GPa (31.2×106 psi) | 460 | 10.5 | 30 | 0.65 |

| 431 | 215 GPa (31.2×106 psi) | 460 | 10 | 25 | 0.7 |

| 440C | 215 GPa (31.2×106 psi) | 430 | 10.4 | 15 | 0.8 |

| 630 | 200 GPa (29×106 psi) | 500 | 10.9 | 30 | 0.71 |

| Type | Corrosion Resistance | Oxidation resistance | Reactivity | Magnetic properties | Flammability |

| 410 | Lowest resistance | Moderate | Low | Ferromagnetic | Nonflammable |

| 420 | More resistant than 410 | Moderate | Low | Ferromagnetic | Nonflammable |

| 440 | More resistant than 420 | Moderate | Low | Ferromagnetic | Nonflammable |

Martensitic SS is a type of stainless steel with several unique properties that set it apart. It is used in a wide range of applications, from mildly corrosive environments to creating maximum strength and stiffness for cold-formed parts. This type of steel is categorized as martensitic because it shares many desirable characteristics that manufacturers look for when selecting steel alloys.

Martensitic steel is a type of steel that tends to be brittle, and welding it is often problematic. However, there is a solution to this problem: quenching and tempering the steel makes it less brittle and more versatile for various applications. The quenching and tempering process refers to heating and rapidly cooling the metal to set it in place quickly. It should be noted that high carbon martensitic stainless steels are mostly not recommended for welded applications, except for alloy 410 Stainless, which can be welded relatively easily.

Various kinds of martensitic steel exhibit magnetic properties as they contain iron in their alloy composition. The molecular structure of these steels is crystalline, which can become magnetic due to the presence of iron. While magnetism can make sorting of metals easier, it can also make welding and other fabrication processes more challenging. It is noteworthy that martensitic steels retain their magnetic properties even after annealing or hardening.

Formability refers to a metal’s ability to be shaped without breaking or cracking. As the carbon content in martensitic steel increases, its formability decreases. Low-carbon forms are challenging to shape, but it is possible.

Martensitic stainless steels are commonly utilized in applications where high mechanical strength is required, although this is only sometimes the case. However, their corrosion resistance level is generally lower than other alloys in the stainless steel family, which limits their use in specific applications.

Sometimes, these materials’ surfaces may have minor rust stains. They can be used in their annealed condition if only limited corrosion resistance or resistance to elevated temperature scaling is needed. However, their highest corrosion resistance is achieved when hardened or tempered.

Martensitic stainless steels are typically provided to manufacturers in the annealed condition as they offer the best forming characteristics. After forming operations, a hardening heat treatment is generally required.

Grades 410 and 420 martensitic stainless steel can also be achieved in cold-worked conditions at relatively low tensile strength levels compared to austenitic stainless steels in the 300 series.

Martensitic stainless steel finds widespread use across various automotive and medical industries.

Advantages

Martensitic steel offers a unique set of advantages for industrial applications.

Disadvantages

Martensitic stainless steel presents certain limitations, such as its complex weldability. Other drawbacks of martensitic steel include:

Martensitic and ferritic steels are two types of stainless steel. Although they are both stainless steel, they have different properties and applications that you should know. Ferritic SSs are magnetic and have low carbon content, which makes them resistant to oxidation. These steels also have high tensile strength and are easy to form and weld. On the other hand, martensitic steels have higher carbon content and can be hardened. This type of steel is best suited for applications that request high strength and wear resistance.

The primary difference between ferritic and martensitic steels is their composition. Ferritic steel is mainly made up of iron and chromium. It also contains small amounts of other elements, such as molybdenum, nickel, and titanium. On the other hand, martensitic steel has a higher carbon content. Additionally, it contains other alloying elements like vanadium and manganese. This higher carbon content makes martensitic steel harder and more wear-resistant than ferritic stainless steel.

Regarding machinability and weldability, ferritic stainless steels have an advantage over martensitic. Ferritic steels are more accessible to machine and weld, while martensitic steels are more difficult to machine and weld due to their higher carbon content.

By uses, martensitic steel is commonly used in applications that request high strength and wear resistance, for example, cutlery, medical instruments, and turbine blades. On the other hand, austenitic stainless steel has a low carbon content, making it highly corrosion-resistant. This is why it is often utilized in food processing and chemical fields, where exposure to corrosive materials is frequent.

By properties, martensitic stainless steel contains more carbon than austenitic stainless steel, making it harder and stronger. However, this increased hardness also makes it more challenging to form and weld. Therefore, it is less commonly utilized in applications that request complicated shapes or intricate welding processes. On the other hand, austenitic SS is the most widely used type, known for its high ductility. It is easy to form and weld, making it a welcome choice for applications that request complicated shapes and complex welding processes.

All in all, martensitic SS is stronger and more wear-resistant than austenitic SS, but it is also more challenging to form and weld. However, both of these stainless steels are highly durable.

Despite their strength and durability, choosing between martensitic and precipitation-hardened (PH) steel can take time and effort. It’s essential to consider their unique benefits carefully.

Martensitic steel is an alloy known for its exceptional strength and toughness, making it ideal for highly durable applications. This type of steel is also simple to machine and forge, making it a welcome option among manufacturers. However, it is important to note that martensitic steel is not as corrosion-resistant as other steels, and its strength may degrade over time because of prolonged exposure to air and moisture.

PH steel is a steel alloy specifically designed to resist corrosion and wear. PH steel is created by adding chromium, molybdenum, and nickel to a martensitic steel base, making it tougher and more tearing-resistant. Compared to martensitic steel, PH steel is also easier to form and shape. However, the downside is that PH steel is more expensive than martensitic steel and is less strong.

When deciding between martensitic and PH steel, it is necessary to think about the intended usage and properties required.

There are five primary categories of stainless steel, each containing multiple types and grades. Stainless steel has many unique features that make it suitable for various applications. Martensitic stainless steel is a versatile steel used in numerous industries. It is highly responsive to multiple forms of heat treatment, which can increase its hardness, strength, and corrosion resistance. Martensitic stainless steel’s strength and corrosion resistance make it ideal for marine, industrial, and medical applications, while its versatility makes it a solution to many problems.