Our Location

If you work with metal, you’re likely aware that even after stamping and machining, many pieces require extra finishing before they can be assembled or shipped. One important final processing step is deburring, which removes burrs and sharp edges that could compromise the part’s safety and functionality.

This blog will discuss the causes of burr formation, the importance of their removal, and the most effective deburring methods.

Table of Contents

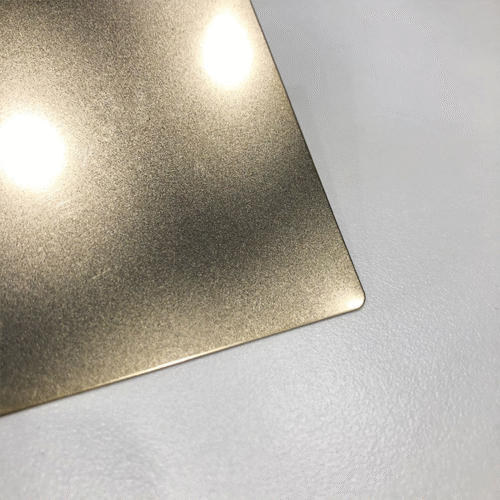

ToggleDeburring is a process that removes imperfections and sharp edges, known as burrs, from materials—typically machined metal products—resulting in smooth edges. During various manufacturing processes, machines perform different operations, such as drilling, milling, engraving, and grinding, to shape metal into multiple parts. These processes can create rough edges that may impact the performance of fasteners and other materials.

There are two main types of burrs: loose and fixed. Loose burrs can be removed easily, while fixed burrs require more tools or advanced deburring methods for removal. Deburring is a crucial procedure as it helps eliminate unwanted protrusions and small ridges from tools and components, ensuring their quality is maintained.

Deburring is an effective technique used after machining or welding operations to produce a smooth and reliable metal piece. Without consistent deburring, burrs can cause issues related to longevity, safety, and functionality:

Burrs can be generated during various machining processes. However, for polished parts, it is possible to eliminate or significantly minimize burr formation. Burrs typically arise during machining or cutting operations. To help clarify how burrs form during these processes, we have categorized the causes of burr formation into two distinct groups.

The machining processes that can leave burrs on metal surfaces include:

Cutting processes that can leave burrs on metal surfaces include:

After these processes, the finished part’s surface may exhibit burrs. Additionally, other factors can also lead to the formation of burrs. These factors include:

If an easy-to-cut material is used, it may not require any post-processing. This is because the material is easy to work with, leaving minimal or no burr.

Burrs can form during machining in three different ways:

The likelihood of burrs being created is minimized when the machine operator is skilled and the machine is set up correctly. However, if an unskilled person machines the part, there may be more burrs than anticipated. Therefore, the outcome is influenced not only by the machining method but also by the operator’s competence.

Deburring is a process of removing burrs from metal items to create smooth edges and surfaces. This step is essential in the manufacturing process, as it dramatically enhances the quality of the part. By eliminating these sharp burrs, the overall performance and functionality of the metal part improve, resulting in a high-quality finish.

Deburring is essential not just for functionality but also for aesthetics. Smoother surfaces and edges enhance a product’s overall appearance, making it more attractive to buyers and users alike. Additionally, removing burrs reduces potential safety hazards by helping prevent accidental cuts or injuries from sharp edges.

There are various methods to deburr metal. Depending on your application and the type of metal, you may choose one of the following techniques.

This is the most common and cost-effective approach. Using simple tools, you can manually scrape away the burrs. It’s easy but time-consuming, making it more suitable for small shops where productivity isn’t a significant concern. The best results are typically achieved with smaller burrs and simpler workpieces.

This method can be used to deburr the inner walls of a hole. A spring-loaded cutting tool mounted on a spindle is positioned to smoothly move through the hole and remove the burr without scratching or damaging the surface. Some cutting tools have a tapered end that creates a chamfer when inserted into the hole.

This process involves using a deburring machine to remove imperfections. Although it is more expensive than manual deburring, it is also more efficient, making it the preferred method in most machining operations. By eliminating the need for hand sanding and grinding, this method increases productivity and enhances the finished product’s quality.

In punch deburring, a punching machine is used with various types of dies—such as rough blanking, fine blanking, and sizing dies—to achieve the desired results. This method is more efficient than manual deburring; however, it requires specialized tools, and complex structures can pose challenges.

Thermal deburring involves generating heat using combustible gases to remove burrs from metal surfaces. This method is especially effective for eliminating hard-to-reach burrs located in cracks or crevices, as well as for removing burrs from multiple surfaces at the same time.

Electrolytic deburring is a process that selectively removes surface imperfections from a workpiece by applying an electric current to convert the metal to its ionic form. Caution is required with this method, as the electrolyte used can be corrosive and may also affect the workpiece’s surrounding surfaces.

This method utilizes a salt or glycol solution to conduct electrochemical energy through the burrs, effectively removing them while preserving the surrounding metal. This process is recommended for working with difficult metals, accessing tight areas, or achieving precise results.

When working with softer metal parts, vibratory finishing offers a gentle yet effective method for deburring. In this process, the part is placed in a vibrating bowl or a rotating barrel with a mixture of abrasive materials and liquid components. As the machine operates, the finishing media continuously rub against the part, effectively removing imperfections such as burrs and sharp edges.

In this method, the parts are placed in a barrel that rotates at high speed, tumbling the pieces together to remove burrs. Barrel tumbling can also be used to clean, descale, and eliminate rust from metal parts.

Deburring machines can be designed for wet applications. Some machined materials produce combustible dust that can easily ignite during metal grinding. Wet machines moisten the dust while working, preventing it from catching fire.

Using specialized equipment, you quickly lower the temperature to make the burrs brittle, then spray pellets to remove them. Freezing can be used when working with smaller pieces with thinner burr walls.

Many deburring tools feature abrasives that effectively remove burrs and smooth cut metal surfaces. Different metals require various grit sizes and materials, but the most commonly used abrasives remain consistent:

Aluminum oxide is widely recognized as the industry standard in various applications. There are two common types of aluminum oxide: closed-coat and open-coat. Closed-coat is ideal for cutting metal and removing weld seams, while open-coat is better suited for woodworking. The particles in these abrasives are quite fragile, so they break down during use. This process ensures that the cutting surface remains sharp at all times.

This specialized abrasive provides a steady and even cut, making it perfect for finishing tasks. While silicon carbide is more expensive than aluminum oxide, it offers greater consistency and can effectively remove burrs without generating heat. As a result, it is an excellent choice for heat-sensitive applications.

Zirconium oxide can be used to grind and clean metals, as well as to remove the edges of hardwood. Before ceramics were invented, zirconium oxide was the strongest and most durable abrasive grain.

Ceramic is a high-quality abrasive due to its hardness and sharpness. It has the longest lifespan of all coarse materials. It efficiently cuts through metal and other hard substances quickly and cleanly without dulling.

When selecting a deburring method for a project, it is crucial to consider the available processes and tools to ensure the best fit for specific requirements. Several factors should guide this selection:

The nature and severity of burrs significantly impact the choice of deburring method. Sharp burrs may necessitate a more aggressive approach, whereas minor burrs might only need gentle treatment.

The material used for the part is crucial, as different materials require distinct deburring techniques. For instance, metals such as aluminum or stainless steel may require different deburring methods compared to materials like plastic, stone, glass, or ceramic.

The availability of specific deburring equipment should be considered. If a particular machine or tool is already utilized for other processes, integrating deburring into the existing machine setup may be more efficient and cost-effective.

When selecting a deburring method, it is vital to consider the part’s size and shape. Larger parts may require a different approach than smaller, more intricate ones. Additionally, complex shapes may need specific deburring tools or techniques to achieve optimal results.

The skill level and expertise of the machine operators should be taken into account. Some deburring methods require specialized training or experience to ensure optimal results and reduce errors.

By thoroughly assessing these factors, manufacturers can select the most appropriate deburring method to eliminate burrs and achieve the desired product quality efficiently.

When making machined parts, several factors must be considered. These considerations can help you save both time and money. Here are some cost-saving tips:

It’s not always necessary to remove burrs from the finished product. For instance, if a part is being sent to another machine shop for further processing, you might choose to leave the burrs intact. This is because there may be additional burrs created in the next step of the process.

Consider saving burr removal for the final step of the manufacturing process. If a burr is found in certain areas during part production, it must be removed. However, if the part being machined poses no risk to anyone and does not affect its functionality, eliminating burrs may not be necessary.

Yes, you can eliminate burrs from your metal parts or make them less noticeable. To achieve this, it’s essential to learn how to use your machine properly and set it up correctly. When grinding, aim to avoid or minimize the formation of burrs. This is especially important when machining expensive or hard materials.

Using abrasive brushes allows simultaneous deburring of multiple edges, saving time and money. Furthermore, these brushes tend to have a longer lifespan, reducing the need to purchase new deburring tools frequently.

It is essential to identify the appropriate deburring method for your part to avoid causing further damage and wasting time and resources. When done correctly, deburring can deliver the smooth, flawless finish your machined components require. However, it’s also important to recognize when deburring is unnecessary, as this can help save both time and costs.