Our Location

During the installation of solar systems, the solar clamp is a crucial fixing method, especially for installing PV modules.

It enhances the stability and security of solar panel installation by pressing the edges of the PV modules, ensuring they are securely fixed onto the bracket or track.

This method enables the panels to be securely fixed to the supporting structure without damaging the power generation area of the PV panel.

Understanding the role of solar clamps in solar panel installations is crucial for ensuring the longevity and efficiency of a solar energy system. This article will explore diverse aspects of solar clamps, including their types, usage, and installation methods.

Table of Contents

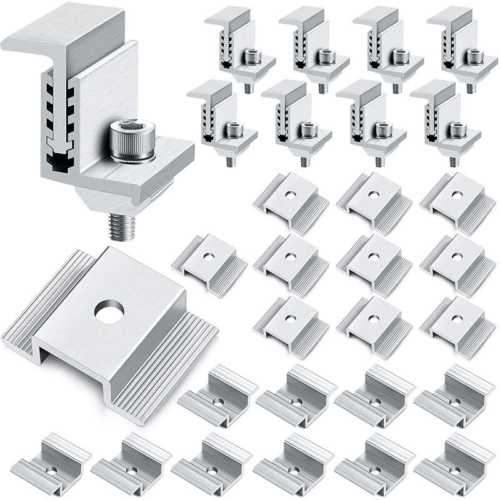

ToggleSolar clamps are designed to meet a variety of panel mounting needs. The following are the most commonly employed types:

End clamps protect the outer edges of the solar panel array. These clamps are crucial for maintaining the system’s stability under different environmental conditions.

Mid clamps are installed between adjacent solar panels to secure them. They are usually made of solar clamp aluminum, providing durability and corrosion resistance.

Some solar clamps include locking mechanisms to prevent theft and ensure a secure grip on the panels.

These clamps are specifically designed for metal roofs, allowing for easy and secure mounting of solar panels without the demands to penetrate the roof.

These components include both mid clamps and end clamps for solar panels, which are essential for building a reliable solar mounting system.

One of the most commonly used materials for solar clamps is stainless steel. It is known for its corrosion resistance, durability, and high temperature tolerance, making it suitable for harsh environments such as deserts and oceans.

Aluminum alloy is also one of the most commonly utilized materials in solar clamps. It features good corrosion resistance, lightweight construction, and high strength, which meet the requirements of photovoltaic modules in diverse environments.

The galvanized steel material is primarily used for ground mounting clamps. It shows good corrosion resistance and is cost-effective, making it suitable for the installation of large-scale photovoltaic power stations.

The process of using solar clamps involves several important steps:

Regularly inspect the solar clamp to ensure that its bolts are tightened, the clamp is undamaged, and the bracket is not deformed, so that any issues can be identified and promptly resolved.

For solar clamps exposed to harsh environments, an anti-corrosion coating can be applied to enhance their corrosion resistance.

Regularly clean and maintain the solar clamp to eliminate dust and dirt. This ensures its surface remains smooth and clean, prolonging its service life.

The selection and use of solar clamps are crucial components of a photovoltaic power generation system. These clamps play a significant role in both the installation and the operation of solar power systems.

By reviewing the classification, materials, installation procedures, maintenance, and advantages of solar panel clamps, we can gain a better understanding of their function. This knowledge will provide strong support for the effective installation and operation of photovoltaic power generation systems.