Our Location

Often referred to as an “auger drill” or “auger drill bit,” an auger is a crucial piece of equipment used in construction. This spiral-shaped tool serves various purposes on-site, depending on the task at hand.

Like other specialty tools, there are several types of augers, which makes it essential to understand what an auger is and how it’s used.

In this article, we will dig into the practical applications of this tool as well as its different types. But first, let’s take a closer look at what an auger actually is.

Table of Contents

ToggleSimply speaking, an auger is a spiral-shaped tool used for drilling holes in the ground and other surfaces.

The spiraling metal shaft equipped with a blade at the end is referred to as “flight” or “flighting.” The flighting rotates to scrape, cut, or extract drilled materials. Debris from these materials (such as soil or ice) is transported along the flighting and ejected from the hole as the blade rotates.

Augers come in various types tailored for different drilling purposes, with each version designed specifically for certain materials, surfaces, or requirements.

Augers, also known by various names such as power earth drills, grain augers, or ice augers, can be used in different applications. They could be powered by an electric motor when attached to a tractor or operated manually.

Today, it is easy to find various auger drilling services and rent the products as well. However, it is also essential to understand these tools and how they evolved into what they are today.

The origins of augers can be traced back to ancient times when early versions of the tool were made from materials such as stone and wood. These antique augers were primarily used to drill holes in simple materials. Their designs typically featured a shaft with a helical spiral or blade, which made the process of drilling holes effective.

Evidence indicates that initial augers were used by civilizations such as the Egyptians and the Romans. Eventually, hand-operated versions were developed throughout Europe during the Middle Ages. These early variants featured metal blades and wooden handles.

As the Industrial Revolution began, it brought about a new era of mechanical innovation, leading to further advancements in augers. This period saw the creation of portable augers and an expanded application of augers across various industries. Additionally, improvements were made in the design of auger teeth, making them sharper and more effective for penetrating hard ground.

Over the past two centuries, devices have evolved significantly, including the development of power augers. These augers, which operated on various sources, from electricity to gasoline, became increasingly prominent.

Today, augers are used in various industries for multiple purposes. Technological advancements have also resulted in developing new materials for manufacturing these products. As a result, there have been significant improvements in durability, efficiency, and operational accuracy.

Ultimately, the evolution of augers has transformed them from hand-operated tools into robust and efficient machines used in various fields.

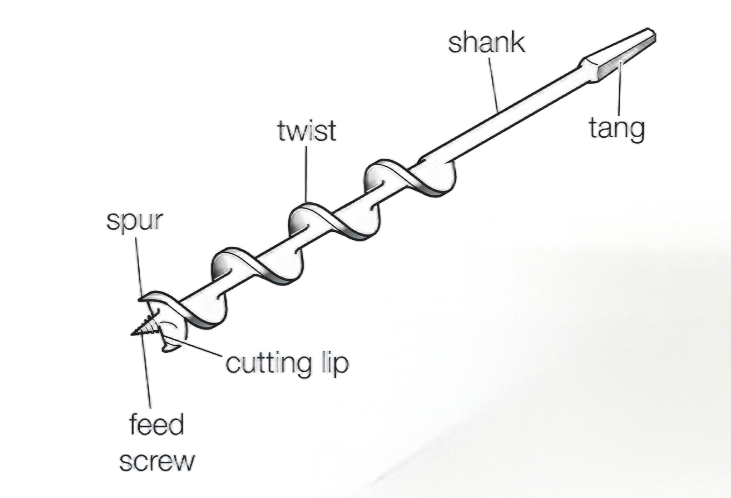

There are six key parts to an auger: the feed screw, cutting lip, spur, twist, shank, and tang.

The tang is located at the top of the auger and is the part that connects to the machine powering it.

The shank of the auger is located between the tang and the start of the blades.

The term “twist” refers to the rotating series of blades that cut and pull the material upward and outwards. For instance, when digging into the ground, loose dirt gets twisted up by these blades, allowing it to be lifted through the shank and removed from the hole.

The cutting tip, feed screw, and spur are all situated in the same place at the bottom of the auger. These components are more pronounced in smaller augers and auger attachments designed for hand tools and drills. They are responsible for making the initial contact with the material and cutting into it. In larger machines and construction auger attachments, the weight and pressure of the drill make it easier to establish this connection. Construction augers are equipped with very sharp points to help penetrate and dig into the materials they are working with.

Augers use a rotating blade that lifts material upward as it turns. While the specific design and operation can differ depending on the type of auger and its intended use, the fundamental mechanism remains consistent across all varieties.

Augers consist of a central shaft or spindle with a helical screw blade wrapped around it. The blade extends along the length of the shaft and is usually made of metal or another long-lasting material. The shape and pitch of the blade’s helix can vary, affecting the auger’s efficiency and performance.

The auger will be attached to a power source that provides rotational motion, like a motor or a drill. When power is applied, the shaft and the attached blade begin to rotate. The direction of rotation could be either clockwise or counterclockwise, depending on the design and specific application.

When the auger is sunk into the ground or placed near the material to be moved, the helical blade starts to engage with the material. As the blade rotates, it functions like a screw, pushing the material upward along the helical flighting. The spiral shape of the blade makes a continuous thread-like structure, which allows for efficient movement of the material.

As the auger rotates, it transports material along the length of its blade. The upward move is aided by the spaces between the blade’s flights, which serve as channels or pockets that hold the material. The rotation of the blade effectively raises and transfers the material upward, creating a continuous flow.

At the upper end of the auger, there is usually a discharge point where the material is discharged. Depending on the exact application, the material can be directed into a container, onto a conveyor belt, or directly to another location.

For optimal results in your project, it is essential to understand the various types of auger drilling machines. Let’s discuss the most typical types of augers available.

These augers are specifically designed for drilling holes in ice and crushing it. They feature sharp blades that efficiently cut through thick layers of ice and are commonly used by fishermen.

You can utilize a grain auger to transport grain and various other bulk materials. They are highly advantageous for loading and unloading grains from trucks, ensuring safe operations.

Earth augers are primarily utilized in the agriculture industry because they can handle various soil types. Their rotating rods and sharp blades efficiently scrape the ground to make holes for any structure.

A hand auger is designed to drill shallow holes and perform small digging tasks. It is lightweight and easy to control since it operates manually. Hand augers can be used in various applications, including gardening, unclogging drains, drilling small fence posts, and other straightforward drilling activities.

These augers are specially designed for gardening and landscaping projects. They are compact and affordable, making them a favorite tool among many garden enthusiasts.

Large-scale construction typically requires larger augers. The taller the structure, the deeper the holes must be drilled for stability. Auger bits can be hex or round, with hex bits offering greater strength.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Now that you know what an auger is, let’s explore its various uses. While this power tool has numerous applications, here are some of the most significant ones:

Augers play a significant role in mining operations. Whether you need to collect samples for analysis or create exploration holes, augers drill precise boreholes in the surface.

In construction, an auger serves various purposes. Most commonly, it is connected to heavy machinery to dig precise holes for foundations, pilings, and soil sampling. Furthermore, it can be used to drill accurate holes in fences and utility poles.

Using augers simplifies landscaping and gardening tasks significantly. They minimize labor and quickly create uniform holes, making it easier to plant any shrub or tree in the ground.

Auger’s aid in installing irrigation systems by drilling holes for drainage channels, ensuring efficient water distribution across fields.

Augers are highly useful for engineers assessing ground conditions by creating soil samples that provide insights into the area’s environmental profile.

For ice fishing, augers are used to drill holes in frozen lakes, allowing easier access to the water below and helping to identify valuable fishing spots.

Augers hold exciting applications in the food industry as they are used for mixing, transporting, and processing bulk ingredients like grains and granules.

In all infrastructure projects, such as bridges and roadways, augers are beneficial for efficient drilling to establish sturdy foundations.

It is evident that augers perform many functions, but how will your daily routine change?

A good auger can significantly enhance the quality of your digging in terms of speed and power. This means you’ll complete your tasks more efficiently and with better results than if you were digging a hole manually. As a result, you can accomplish more work in a single day, whether that involves drilling additional holes or carrying out other farming or construction tasks. This efficiency can save you both time and money in the long run.

An auger drill is a highly versatile tool, allowing operators to easily switch out different components to tailor the device for specific tasks. Various attachments, such as a hole cleaner, log splitter, or log planer, can be swapped out to enhance the functionality of your auger drill. This adaptability increases the tool’s versatility and saves you money by eliminating the need to purchase entirely new equipment.

One of the most significant advantages of using an auger is its extended reach. In certain situations, you may need to dig deeper holes. The increased reach attachment allows the drill to work around various obstacles, such as holes, plants, and fences. Additionally, this more extended reach enables you to tackle more challenging tasks. Overall, an earth auger attachment provides much greater versatility than a handheld option or simply using a shovel.

An auger undoubtedly saves time and also offers health benefits to the user. Digging holes can be tiring and impose considerable physical demands on the body. Using an auger can significantly reduce the strain involved, making the process much less physically taxing.

An auger is often more efficient than manual labor, whether performed by an individual or a team. This allows you to utilize workers’ specific skills better, whether they are specialized or common laborers. As a result, you can run a more efficient company without hiring additional staff while minimizing the risks associated with physical digging.

Augers have limited power and struggle with cutting rocks and heavy clay. To avoid complications, it’s better to choose more robust machinery for effectively cutting through rocks.

An auger can drill holes ranging from 3 to 95 feet deep. If you need to go deeper than 95 feet, an extension rod can be added to the auger.

You should clean it regularly after each use and always inspect it for any signs of tear and wear. Additionally, lubricate the moving parts often to ensure smooth operation.

We hope you now understand what an auger is and how it can be used. Choose the right auger to save time and effort, whether you have a small project or a heavy-duty task. In addition to improving efficiency, augers enable you to complete your work confidently and enjoyably.